公司简介

SPI激光公司成立于2000年,致力于将英国南安普顿大学光电研究中心的高新技术产业化。并于2003年推出了首台商用光纤激光器。SPI公司的激光器是为系统集成而设计的,符合所有相关的EN,UL和CE认证标准。光纤激光器能量转换效率高,其效率为YAG激光器的10倍,成为众多用户环保节能的首选。 产品包括:脉冲光纤激光器10W-30W,连续可调制光纤激光器10-400W,以及10W @1550nm和20W @1565nm光纤激光器模块及系统。

产品列表

redPOWER® CW Fiber Lasers

Our range of redPOWER® CW Fiber Lasers are efficient and flexible Lasers providing exceptional levels of power and control for cutting, welding and drilling.

PowerDepending upon customer requirements Lasers can be supplied with a variety of power outputs from 100W all the way up to 6kW. VersatilityOur redPOWER CW Fiber Lasers can be supplied in a variety of formats; whether you are looking for a standalone unit to incorporate into an existing machine / system or, want a fully functioning system delivered in a ‘plug and play’ format for instant performance. Whatever the requirement, you are sure to find a solution amongst our flexible array of redPOWER CW Lasers. | Fit & Forget Technology All our redPOWER CW Fiber Lasers are designed to be maintenance free, utilising ‘Fit & Forget’ technology, allowing you to focus on output, rather than time consuming maintenance schedules. Designed for manufacturability and reliability redPOWER sets new standards of product quality, backed by comprehensive warranties as standard. |

CLICK AN IMAGE FOR DETAILS

redPOWER® QUBETell me more about redPOWER QUBE (300W – 1.5kW) |

redPOWER® PRISMTell me more about redPOWER PRISM (300W – 1.5kW) |

redPOWER® PRISM Multi kW OEMTell me more about redPOWER PRISM Multi kW OEM (3kW – 6kW) |

redPOWER® QUBE Multi kW LaserTell me more about redPOWER QUBE Multi kW Laser (3kW – 6kW) |

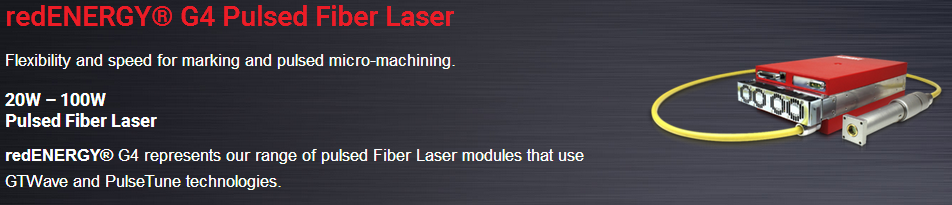

Operating in the nanosecond pulse duration regime these Lasers are widely used in diverse applications, offering users unrivalled versatility and flexibility.

| Flexible Lasers are the tool of choice no matter what the material as they produce permanent marks with a non-contact process at high speed with high precision. Laser marking requires no consumables and marks are computer generated and are therefore highly flexible. redENERGY® G4 has been designed with specific attention to enhance the ease of OEM integration, enabling easy adoption of the full product features and range. redENERGY® G4 is designed to benefit high volume manufacturing, where it yields unprecedented reliability and consistency. Innovative TechnologyOur G4 model is the 4th generation redENERGY® pulsed product platform and is the pinnacle of pulsed nanosecond technology, with enhanced features for micro-machining, moving our PulseTune enabled Lasers to a new level. PulseTune technology offers the OEM integrator highly flexible control over pulse width and peak power. The unique PulseTune function enables market leading repetition rates whilst maintaining peak power. | Versatile The key differentiator of our redENERGY Pulsed Lasers is the versatility of up to 40 selectable waveforms and the benefits that accompany its flexibility. The ability to optimise key pulse characteristics to individual applications gives enhanced process quality and productivity. No MaintenanceEvery care has been taken at the design stage to ensure that our products offer a long and maintenance free life. redENERGY® G4 Lasers are all maintenance free, utilising ‘Fit & Forget’ technology, allowing you to focus on output, rather than time consuming maintenance schedules. Designed for manufacturability and reliability redENERGY® G4 sets new standards of product quality, backed by an industry leading 3 year warranty as standard. |

Laser Functionality:

RM Series (Reduced Mode)

HS Series (High Spec)

| EP Series (Extended Performance)

|

Beam Quality Options

S Type – Single mode M2 <1.3 Generating very fine spot size <20 microns with high power stability and large depth of focus. Ideally suited to applications requiring small feature sizes. Z Type – M2 <1.6 Offering higher peak power and pulse energy with only minor increase in spot size with good depth of focus. L Type – Low Mode M2 1.6 – 2.0 General marking applications giving slightly larger spots and features that are more appropriate to making marks visible to the naked eye. H Type – High mode M2 2.5 – 3.5 Offering high pulse energies, and peak powers and even larger spots ideal for wide lines, filled font type applications and large area coverage. |  |

![]()

![]()

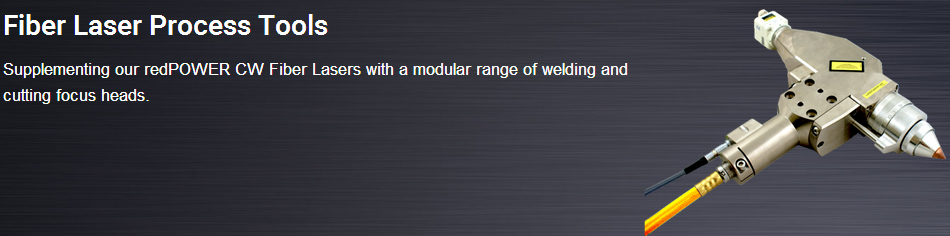

A Range of Versatile Process Tools

| In manufacturing one size does not fit all, which is why we offer a range of specialist process tools. Our re-collimation units, cutting and welding heads are modular in design so a package can be tailored to your unique needs. Ease of use: The interchangeable lens module with fast-change cover slide and focus lens cell mean it is easy to swap lenses according to the application. A variety of diffraction-optimised lens sizes are available for our Fiber Laser range. Fine focus control: For single mode Fiber Lasers using a typical 1:1 imaging onto the work piece, the Rayleigh range is only 100µm. To optimise kerf width and cut quality, the focus position must be fine-tuned. Therefore, our cutting heads feature a high resolution (<50µm) real-time control of the focus position over a ±2.5mm range. This eliminates the need to move the whole process tool, which would affect the stand-off position. Assisted gas flow: The gas routing into the nozzle is optimised for maximum velocity, uniformity and extended parallel flow to achieve the best possible cut. The gas flow is integrated so there are no unsightly external gas pipes to interfere with part access. | Air knife: For welding applications, we offer an air knife, which delivers high velocity airflow across the cover glass to efficiently deflect weld spatter and extend the cover glass life. Through the Lens (TTL) illumination: This integral light allows users to clearly see their welding and cutting applications, when using the CCTV camera option. Height-sensing cutting head: Available for our Fiber Laser range, with or without viewing capability, our height-sensing cutting head automatically detects contours in the processed material. Any variations from set focus positions triggers an error correction signal. Robust, compact design: Time and money are precious commodities for any business. Therefore, our process tools are robustly designed to be maintenance-free, even in the most demanding applications. They also fit compactly into small spaces so users are not faced with the prospect of redesigning their workstation enclosure. |

Fiber Laser Process Tools

A complete range of industrial focusing heads and optics solutions designed to optimise the exceptional beam quality of our range of CW Fiber Lasers for your applications.

|  |

Luminator™ Process Tools

A complete range of industrial focusing heads and optics solutions for cutting, welding and heat treating.

|  |

Luminator™ Fiber Optics

A standard feature on our redPOWER CW Lasers. Complete field-retrofittable upgrade packages are available for some of our previous generation Lasers; ask your sales representative for more information.

|  |

Fiber Laser Scan Head System

| A modular range of flexible scanning components, providing a complete solution to your high speed processing applications. The scan head is driven by our powerful and fully integrated FiberView™ Scanning Head User Interface (SHUI). Our Scanning System has been specifically designed to enhance the processing capabilities of our range of redPOWER CW Fiber Lasers, enabling the beam to be deflected precisely and quickly to any location across the working area.

|

|

Scan Head User Interface (SHUI)

SHUI is a self optimising, pre-emptive system that is seamlessly integrated with a selection of products from our redPOWER CW Fiber Laser range.

|  |