公司简介

Founded in 1995 by optics manufacturing experts (in both commercial and military optics), Rainbow Research Optics, Inc. (RROI) has been exclusively serving the High Precision Optical Markets in the United States and around the world. We specialize in custom prototype and high precision optics applications. We can provide high volume quantities for production lines of OEM system manufacturers.

产品列表

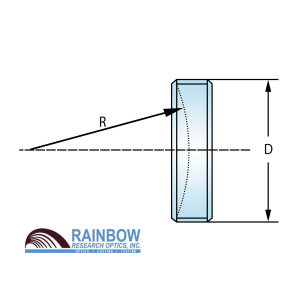

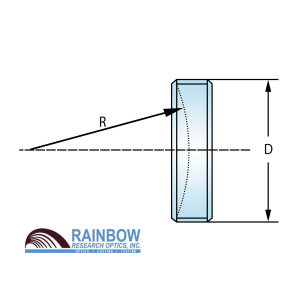

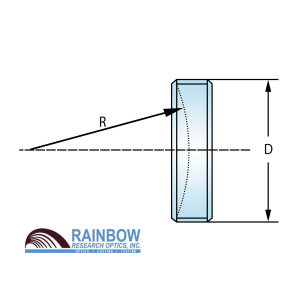

SPHERICAL LENSES

Your One-Stop Source for Spherical Lenses

Your One-Stop Source for Spherical Lenses

From prototype to production, Rainbow Research Optics, Inc (RROI) designs, manufactures, and coats spherical lenses. Spherical lenses are one of the most basic optical components to produce. With complete in-house capabilities, RROI is able to offer spherical lenses at the lowest pricing with fast delivery times.

From 3.0 mm to 16 in. diameter

From 3.0 mm to 16 in. diameter

Scratch dig up to 10-5 and tight tolerances

Scratch dig up to 10-5 and tight tolerances

Stock inventory

Stock inventory

Quick find: • Plano Convex • Plano Concave • Bi-Convex • Bi-Concave • Bestform • Achromatic Doublet

STANDARD SPHERICAL LENSES

Customization is available beyond what’s listed. Contact us with your requirements.

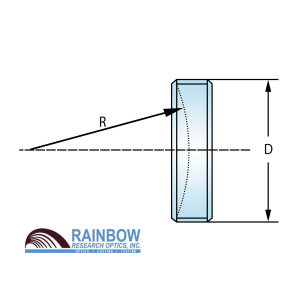

| Convex Lenses – Fused Silica – Spherical | (part code: PXUV) |

Substrate: UV Fused Silica

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Convex Lenses – BK7 – Spherical | (part code: PXC) |

Substrate: BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Convex Lenses – CaF2 (VUV) – Spherical | (part code: PXCF) |

Substrate: VUV grade CaF2

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Convex Lenses – CaF2 (IR) – Spherical | (part code: PXCFIR) |

Substrate: IR grade CaF2

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/4 @ 633 nm

Surface Quality: 40-20 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Convex Lenses – MgF2 (VUV) – Spherical | (part code: PXMF) |

Substrate: VUV grade MgF2

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Convex Lenses – SF11 – Spherical | (part code: PXSF11) |

Substrate: SF11

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Concave Lenses – BK7 – Spherical | (part code: PVC) |

Substrate: Bk7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Concave Lenses – Fused Silica – Spherical | (part code: PVUV) |

Substrate: UV Fused Silica

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Concave Lenses – SF11 – Spherical | (part code: PVSF11) |

Substrate: SF11

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

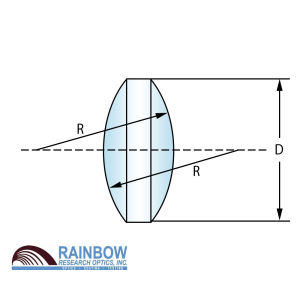

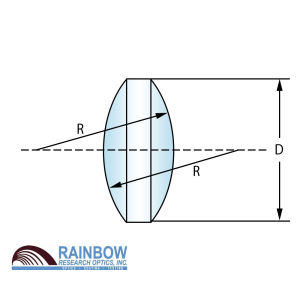

| Bi-Convex Lenses – BK7 – Spherical | (part code: BXC) |

Substrate: BK7

Diameter Tolerance: +0.0/-0.20mm

Thickness Tolerance: ±0.25mm

Surface Irregularity: λ/10 @ 633nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: <3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3mm face width at 45° |  |

| Bi-Convex Lenses – Fused Silica – Spherical | (part code: BXUV) |

Substrate: UV Fused Silica

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

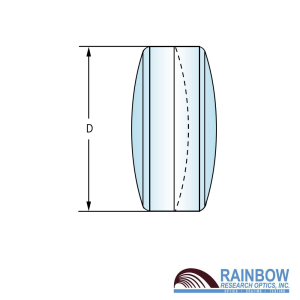

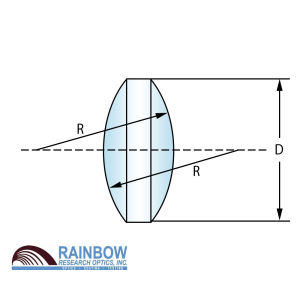

| Bi-Concave Lenses – BK7 – Spherical | (part code: BVC) |

Substrate: BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Bi-Concave Lenses – Fused Silica – Spherical | (part code: BVUV) |

Substrate: UV Fused Silica

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

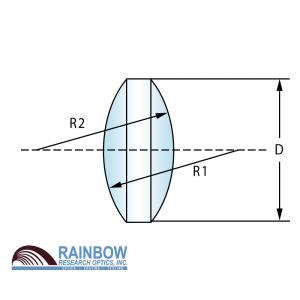

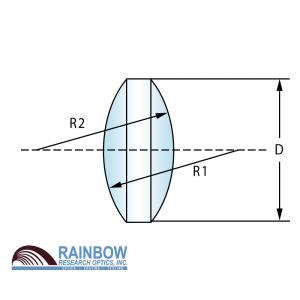

| Positive Bestform Lenses – Spherical | (part code: BFCXC) |

Substrate: UV Fused Silica or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

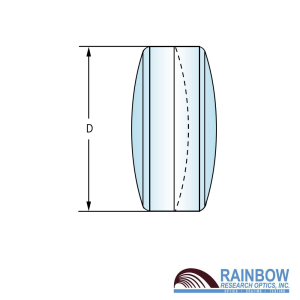

| Achromatic Doublet Lenses – Spherical | (part code: ADL) |

Substrate: Contact us

Radius Tolerance: ±1.0%

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/4 @ 633 nm

Surface Quality: 40-20

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

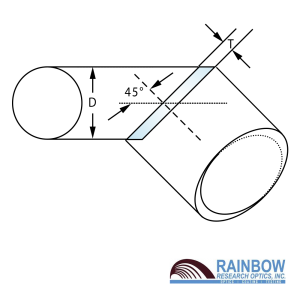

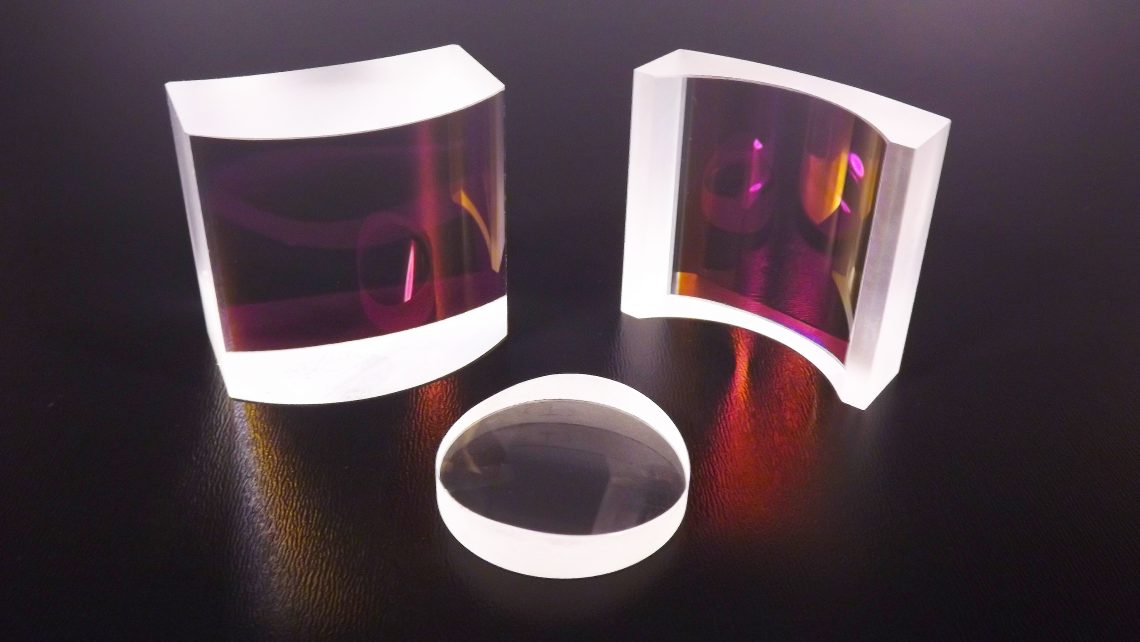

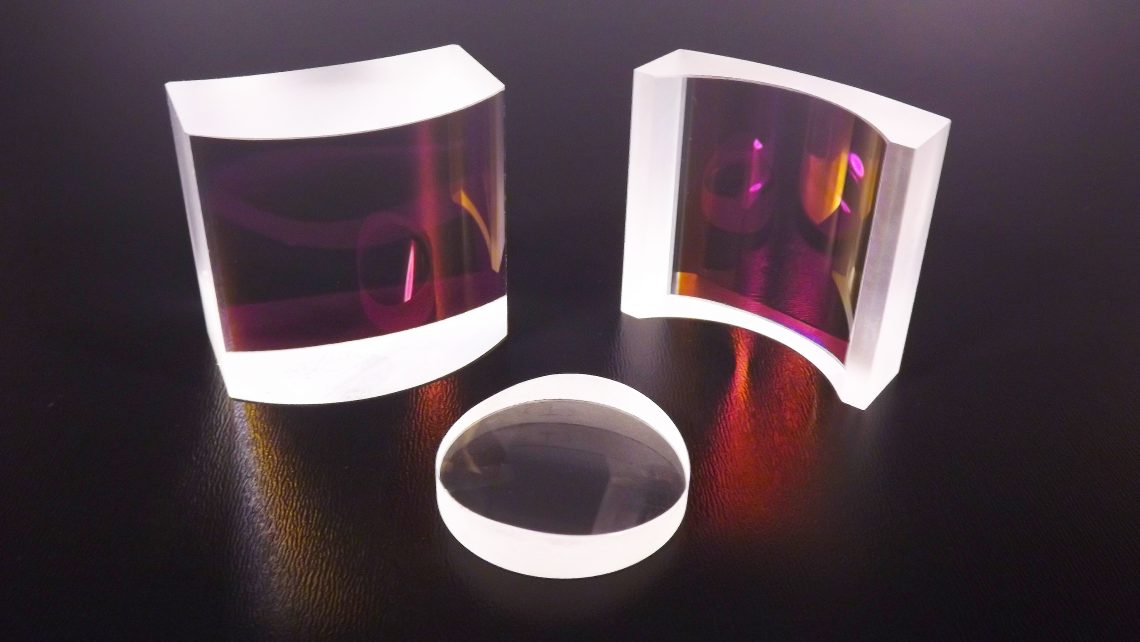

CYLINDRICAL LENSES

Cylindrical lenses are designed for applications requiring one-dimensional shaping of a light source. They are offered in either plano-concave or plano-convex configurations, which are meant to expand or focus light, respectively.

Cylindrical lenses are designed for applications requiring one-dimensional shaping of a light source. They are offered in either plano-concave or plano-convex configurations, which are meant to expand or focus light, respectively.

Your One-Stop Source for Cylindrical Lenses

From prototype to production, Rainbow Research Optics, Inc (RROI) designs, manufactures, and coats cylindrical lenses. Employing only expert polishing and grinding engineers, RROI has the ability to offer cylindrical lenses at the lowest pricing with the fastest delivery times.

Choose from N-BK7 glass, UV fused silica, or CaF2, all of which are available un-coated or with an anti-reflective (AR) coating. For applications requiring minimal aberration, ask us about acylindrical lenses and cylindrical achromatic doublets.

Quick find: • Round Cylindrical • Square Cylindrical • Rectangular Cylindrical

STANDARD CYLINDRICAL LENSES

Customization is available beyond what’s listed. Contact us with your requirements.

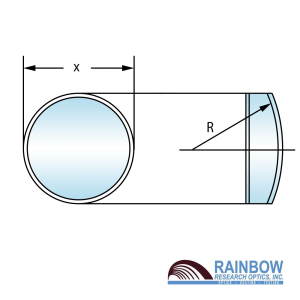

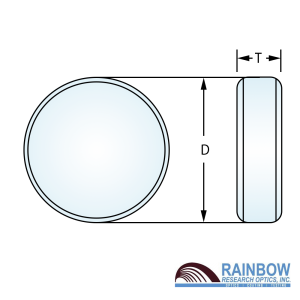

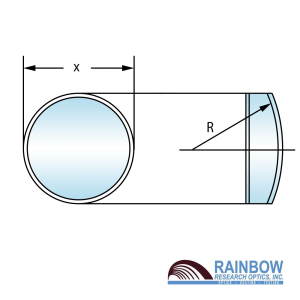

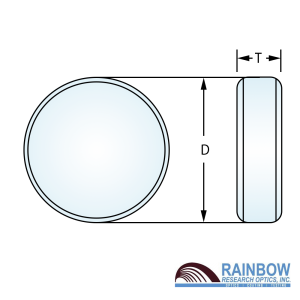

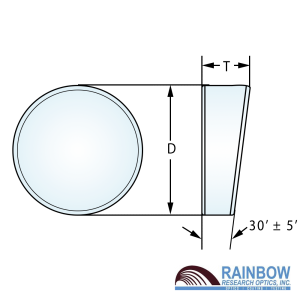

| Round Plano-Convex Lenses – Cylindrical | (part code: CLPXCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

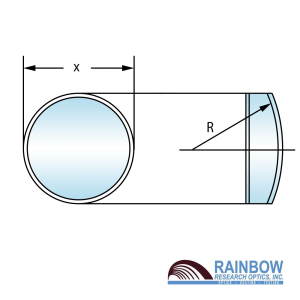

| Round Plano-Concave Lenses – Cylindrical | (part code: CLPVCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

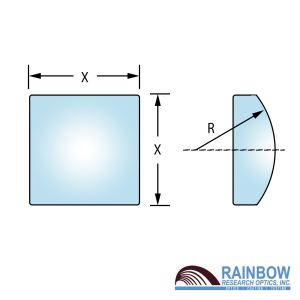

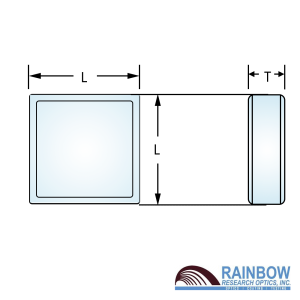

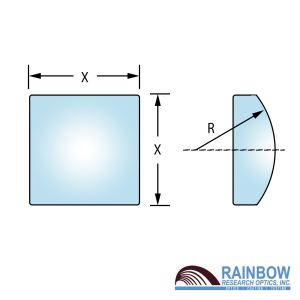

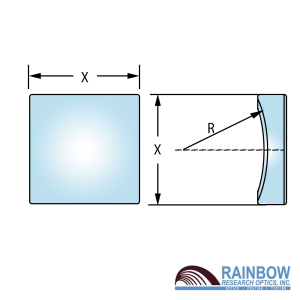

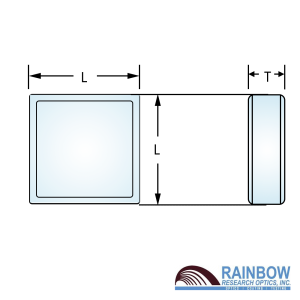

| Square Plano-Convex Lenses – Cylindrical | (part code: CSPXCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

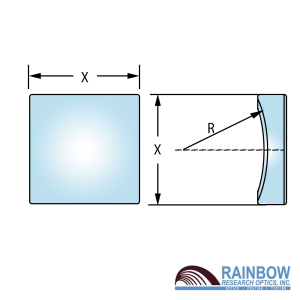

| Square Plano-Concave Lenses – Cylindrical | (part code: CSPVCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

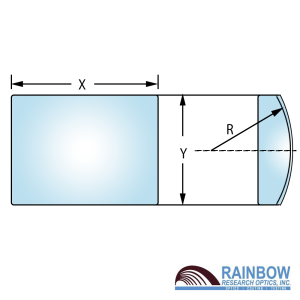

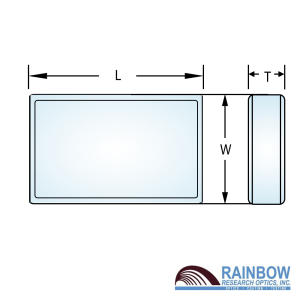

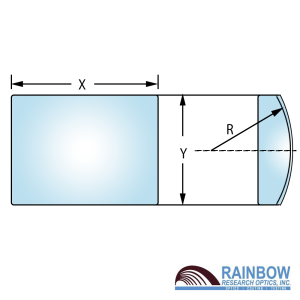

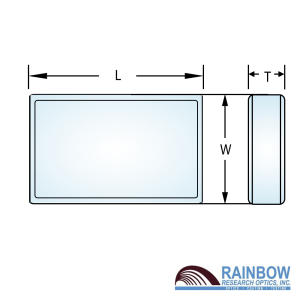

| Rectangular Plano-Convex Lenses – Cylindrical | (part code: CRPXCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Rectangular Plano-Concave Lenses – Cylindrical | (part code: CRPVCF) |

Substrate: VUV CaF2, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Irregularity: λ/2 for Y-direction, λ/4 for X-direction @ 633 nm

Surface Quality: 20-10 laser quality

Focal Length Tolerance: ± 0.5%

Centration Error: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

WINDOWS AND OPTICAL FLATS

Optical Windows are often used to create a physical barrier between two different environments – preventing two gases from mixing together, separating liquids from air, keeping a sealed system in vacuum. In many optical systems, a window is used to protect more expensive optical components (within an assembly) from back-splatter, out-gassing or other possible damage.

While it can take nearly any form, most windows are either round or rectangular in shape. All windows are fabricated from optically transparent material, with two flat (or plano) polished surfaces.

Your One-Stop Source for Optical Flats & Windows

From prototype to production, Rainbow Research Optics, Inc. (RROI) manufactures and delivers precision grade and commercial quality windows to address applications in the ultraviolet (UV), visible, and infrared (IR) wavelength ranges.

Standard and specialty materials

Standard and specialty materials

In-house fabrication, polishing, and coating

In-house fabrication, polishing, and coating

Stock inventory

Stock inventory

Quick find: • Plane Windows • Parallel Windows • Interferometer Flats • Large Wedge Windows • Square Windows • Rectangular Windows • Elliptical Windows • Brewster Windows

STANDARD & CUSTOM WINDOWS

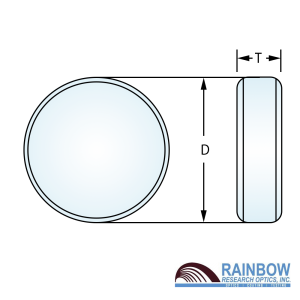

| Plane Windows – Wedge < 3 min. | (part code: WI) |

Substrate: VUV MgF2, CaF2 (VUV), Caf2 (IR), SUPRASIL 1, Sapphire, Silicon, Germanium, Zinc Selenide, or Zinc Sulfide

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Transmitted Wavefront: measure at 633 nm

Wedge: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Parallel Windows – Wedge < 10 sec. | (part code: PW) |

Substrate: VUV MgF2, CaF2 (VUV), Caf2 (IR), SUPRASIL 1, Sapphire, Silicon, Germanium, Zinc Selenide, or Zinc Sulfide

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Transmitted Wavefront: measure at 633 nm

Wedge: < 10 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

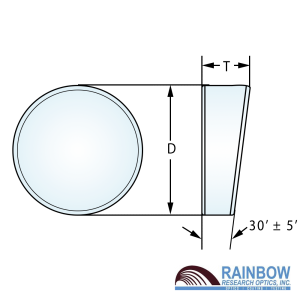

| Interferometer Flats – Wedge 30 ± 5 min. | (part code: IF) |

Substrate: SUPRASIL 1, UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Flatness: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Wedge: 30 ± 5 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Large Wedge Windows – 1°, 2°, and 3° | (part code: WW) |

Substrate: UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Flatness: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Wedge: 30 ± 6 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Square Windows | (part code: SW) |

Substrate: UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Flatness: measure at 633 nm

Surface Quality: 10-5 laser quality

Wedge: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Rectangular Windows | (part code: RW) |

Substrate: UV Fused Silica, or BK7

Diameter Tolerance: +0.0/-0.20 mm

Thickness Tolerance: ±0.25 mm

Surface Flatness: measure at 633 nm

Surface Quality: 10-5 laser quality

Wedge: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

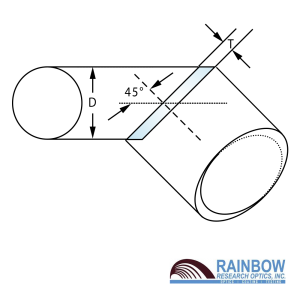

| Elliptical Windows | (part code: EW) |

Substrate: UV Fused Silica, or BK7

Diameter Tolerance: + 0.0/-0.20 mm

Thickness Tolerance: ± 0.25 mm

Surface Flatness: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Wedge: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

| Brewster Windows | (part code: BW) |

Substrate: SUPRASIL 1 or UV Fused Silica

Diameter Tolerance: + 0.0/-0.20 mm

Thickness Tolerance: ± 0.25 mm

Surface Flatness: λ/10 @ 633 nm

Surface Quality: 10-5 laser quality

Wedge: < 3 arc min.

Clear Aperture: > 85% of diameter

Edge Bevel: 0.3 mm face width at 45° |  |

laser-mirrors

Mirror Substrates

Optical Filters

Beamsplitters

Waveplates

Polarizers

Prisms

COATINGS

Optical coatings are specified and designed to enhance or reduce the reflectance, transmittance, or polarization properties of optical components. Coatings can be made from one or more layers of dielectric, IR, or metallic materials. Each coating is designed for a specific wavelength or wavelength range.

Our products are available either coated or uncoated. If coated, we can provide either standard or custom coating designs.

OUR WORLD-CLASS COATING TEAM

Rainbow Research Optics, Inc. proudly employees a world-class coating team capable of meeting tighter tolerances than many of our competitors. Equipped with resistance heated and electron beam evaporation coating chambers, we can produce coatings ranging from the ultra-violet to the far infra-red wavelengths.

Wavelengths from 193 nm to 14 µm

Wavelengths from 193 nm to 14 µm

Fast custom designs

Fast custom designs

ITO coatings and in-house environmental testing

ITO coatings and in-house environmental testing

Quick find:• 45 Degree Thin Film Polarizer Coating • Single Layer Anti-Reflection (AR) Coating • Laser Line V-Coating • Double-V AR Coating• Broadband Multilayer AR Coating • Laser Line High Reflector • Partial Reflector • Edge Pass Coating • Beamsplitter Coating • Metallic Coating

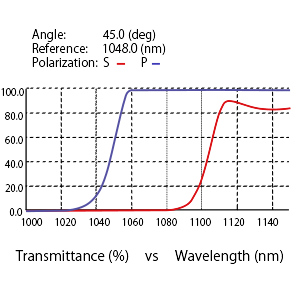

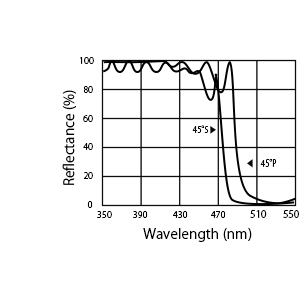

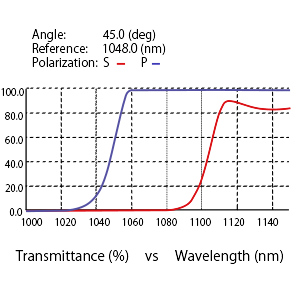

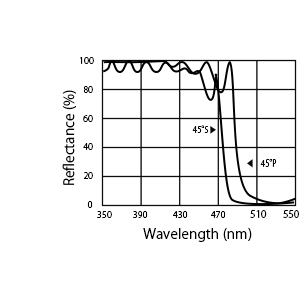

| 45 Degree Thin Film Polarzier Coating |

|

10.23.2007 Our Engineers Have

Done It! We Have Developed.

Extinction Ratio: 200:1

Back Side AR Coating |  |

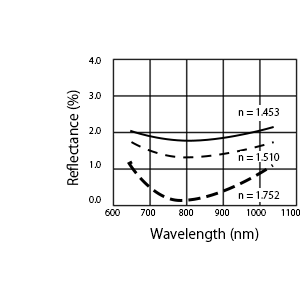

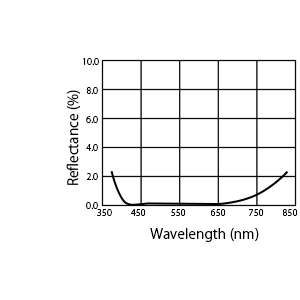

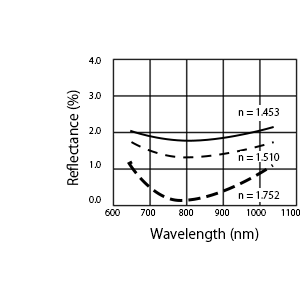

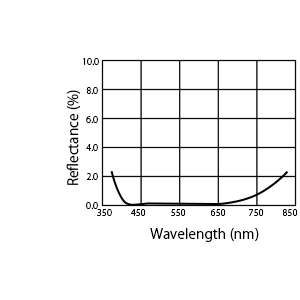

| Single Layer Anti-Reflection (AR) Coating |

|

MgF2 is commonly used in AR coating for lenses, windows and beam splitters

because of its almost ideal refractive index (1.35 @550nm) and high durability.Single layer AR coating is available for almost any angle of incidence and any

wavelength from UV to IR. A layer of MgF2 on a glass of Fused Silica substrate

reduces surface reflectance to < 1.5% per surface over a wide range. |  |

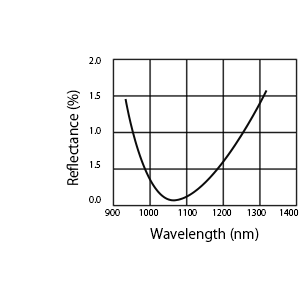

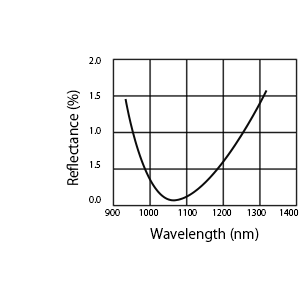

| Laser Line V- Coating |

|

V-coating is multilayer AR coating that reduces surface reflectance <0.25% at 0

degree AOI at the chosen single wavelength . Using V-coating on Fused Silica

Substrate can provide exceptionally high external transmittance. Rainbow Optics

is producing V-type AR coating for any wavelength from 193nm to 2940nm. |  |

| Double-V AR Coating |

|

These Double-V AR coating is providing the performance of V-coating for two

selected wavelengths. This coating is useful for optics that must transmit. visible

alignment laser as well as NIR process beam (ex. Nd:YAG laser). Double-V

coating provides an average reflectance <0.25% for NIR region and <0.5% for

visible region at normal AOI. |  |

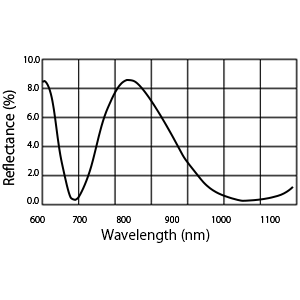

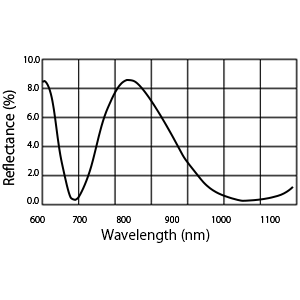

| Broadband Multilayer AR Coating |

|

This BBAR coating provides the minimum reflectance for wide spectral range.

Average reflectance losses are reduced to <0.5% per surface for specified

wavelength range. Due to the high number of layers, this coating are more

sensitive to incident angle than the single layer AR. |  |

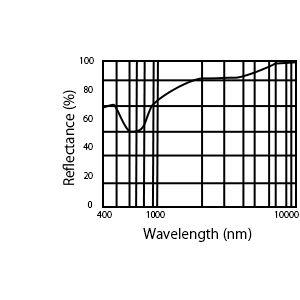

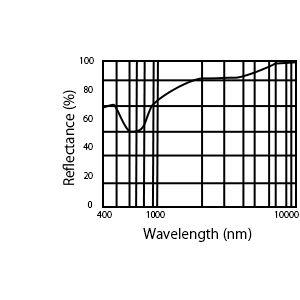

| Laser Line High Reflector |

|

This coating is optimized to give >99% of reflectance at specific laser wavelength.

It may be used as a rear cavity reflector at 0 deg AOI, extra cavity used in beam

delivery or turning at 45 deg incident angle. In addition to the standard laser line

coating, we offer broadband high reflector for multi-spectral application. It is more

efficient than any metal coating and may be used with lasers or broadband sources. |  |

| Partial Refletcor |

|

Partial reflective coating is used as laser output couplers at 0 deg AOI. An

appropriate output coupler should be selected to maximize the output power

/ energy ratio. Rainbow Research Optics offers high quality laser cavity coating

for low scattering. Also, dividers at 45 deg AOI for the specific wavelength. They

have an AR V-coating applied to the rear surface. |  |

| Edge Pass Coating |

|

Edge pass coating is characterized by an abrupt change between a region of

transmittance and reflectance. A long wave pass coating reflects shorter

wavelengths and transmits longer wavelength. A short wave pass coating reflects

longer wavelengths and transmit shorter wavelengths. Cut-on/off wavelength is

the wavelength at which the transmission is 50% of its peak value. A common

use for this coating is to combine them with a filter or detector response in

order to define a wavelength range. |  |

| Beamsplitter Coating |

|

Beam splitters are used to separate or combine two beams of light. Plates are

used for most laser applications as they exhibit low absorption. Cubes are

convenient, protected form for low power applications. Polarizing beam

splitter coating provide an extremely efficient method of driving a randomly

polarized incident laser beam into the “S” and “P” components of the beam

for specific wavelength or wavelength range. |  |

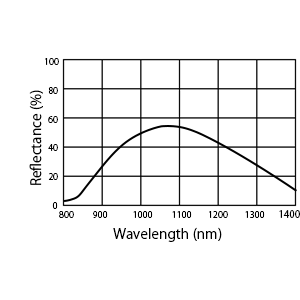

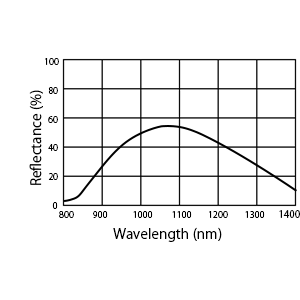

| Metallic Coating |

|

Metallic coating has lower peak reflectance, mechanical durability and damage

threshold than dielectric coatings. The advantages of metallic canting are low

cost, extremely broadband performance and insensitivity to input angle of

incidence and polarzation |  |

Your One-Stop Source for Spherical Lenses

Your One-Stop Source for Spherical Lenses From 3.0 mm to 16 in. diameter

From 3.0 mm to 16 in. diameter Scratch dig up to 10-5 and tight tolerances

Scratch dig up to 10-5 and tight tolerances Stock inventory

Stock inventory Cylindrical lenses are designed for applications requiring one-dimensional shaping of a light source. They are offered in either plano-concave or plano-convex configurations, which are meant to expand or focus light, respectively.

Cylindrical lenses are designed for applications requiring one-dimensional shaping of a light source. They are offered in either plano-concave or plano-convex configurations, which are meant to expand or focus light, respectively. Standard and specialty materials

Standard and specialty materials In-house fabrication, polishing, and coating

In-house fabrication, polishing, and coating Stock inventory

Stock inventory Wavelengths from 193 nm to 14 µm

Wavelengths from 193 nm to 14 µm Fast custom designs

Fast custom designs ITO coatings and in-house environmental testing

ITO coatings and in-house environmental testing