公司简介

LaVision was founded in 1989 as a spin-off from Max Planck Institute and Laser Laboratory in Goettingen, Germany. LaVision cooperates with leading scientists, research institutions and companies around the globe. Among the major cooperation partners are the Laser Laboratory Goettingen, the University of Delft, German Aerospace Center (DLR), Technical University Darmstadt and the Karlsruhe Institute of Technology (KIT).

产品列表

FlowMaster

PIV/ PTV-systems

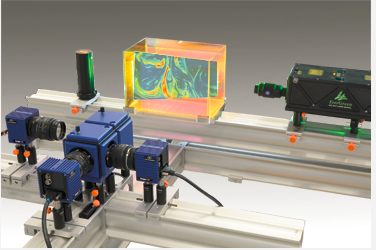

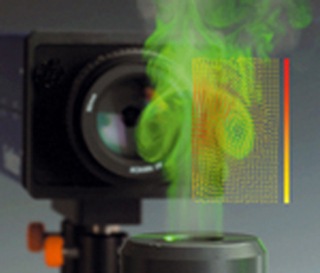

The LaVision FlowMaster system family evaluates three-dimensional velocity vector fields from scattered light patterns of particles or droplets seeded into the flow (liquid or gas). Techniques like Particle Image Velocimetry (PIV) and Particle Tracking Velocimetry (PTV) are supported. LaVision's FlowMaster PIV cameras can record two successive images within min. time <100 ns for ultrafast cross-correlation and speeds up to Mach 4. The PIV cameras offer highest sensitivity and allow the use of very small particles (or droplets). An image field of up to 29 million pixels combined with up to 16 bit dynamic range gives an unsurpassed spatial resolution. Programmable precise timing sequences in combination with flexible and speedy software evaluation complete the package.

Standard 2D-PIV (2D2C) measures two velocity components in a plane using a single CCD or sCMOS camera.

Stereo-PIV (2D3C) measures three velocity components in a plane using two cameras.

Time-resolved PIV measures two or three velocity components in a plane at high frame rates up to 25000 fps (frames per second) with full camera resolution.

Tomographic PIV (Tomo-PIV) measures three velocity components in a volume (3D3C) using two or more cameras.

Micro-PIV measures two or three velocity components of particle seeded flows with micron scale spatial resolution.

Applications

liquid and gas flow investigations in wind tunels, water channels, in-cylinder engines industrial flow systems, compressors, turbines, fans, pumps, Micro Electro Mechanical Systems (MEMS)

Information

velocity fields (strain, vorticity etc.)

flow visualization

System Features

self-calibration for 3D stereoscopic PIV eliminates calibration errors

beam delivery. articulated arms, compact sheet optics

particle seeder

general purpose synchronization device

online data storage, real-time data recording for many hours

data analysis on CPU and GPU

distributed computing on network PCs

Specials

underwater PIV setup for towing tanks with smart optical access

in-cylinder flow analysis with laser and camera endoscopes

————————————————————————————————————————————————————

FluidMaster

FluidMaster is a complete laser imaging system family for the quantitative visualization of thermal flows and mixing processes in fluids. Instantaneous concentration and temperature fields are measured with high spatial and temporal resolution.

Applications

investigation of fluid mixing, thermal flows and flow structures, flow visualization in wind tunnels and turbomachinery applications, air film cooling, hydrodynamics ... for further information see Applications in Fluid Mechanics

Information

quantitative visualisation of concentration and temperature fields in fluids

pH-imaging and degree of reactive mixing in liquids

gas density measurements in thermal flows

System Features

integrated turnkey laser imaging systems based on application matched best selection of laser and camera

complete hardware control using DaVis software

accurate hardware and signal calibration

most effective LIF excitation techniques

Rayleigh thermometry package for thermal gas flows

oxygen (O2)-LIF imaging module

Specials

3D-imaging setups

time resolved imaging, digital film recording

————————————————————————————————————————————————————

FlameMaster

LaVision's FlameMaster system family is designed to help the scientific and engineering community to find new concepts for the realization of more efficient and cleaner combustion devices.

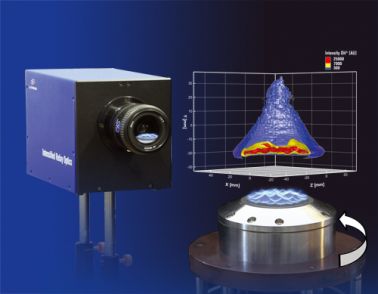

3D Flame Imaging

Reconstructed time-averaged 3D OH* distribution in a premixed CH4 - air flame

Principle of tomographic flame imaging using a single camera:

An intensified CCD camera records the line-integrated projections of the OH* emission from 15 viewing angles of a premixed CH4-air flame featuring a strongly corrugated 3D-flame front. The tomographic reconstruction software module in DaVis generates from these 15 2D-images the mean volumetric OH* distribution of the flame.

————————————————————————————————————————————————————

EngineMaster

EngineMaster

Multi-functional laser imaging systems investigating all stages of internal combustion processes like fuel injection, air-fuel mixture formation, ignition, combustion and pollutant formation.

Applications

all kind of internal combustion phenomena:

fuel injection, air-fuel mixture preparation

in-cylinder temperature fields, ignition and flame propagation, pollutant and soot formation

... for further information see Applications in Engines

Information

liquid and vapor fuel concentration fields

local air/fuel ratios (lambda-maps)

in-cylinder temperature during mixture formation

localization of knock centers

flame front propagation

combustion species concentration (OH, NO, CH ...)

soot concentration and primary soot particle size

System Features

integrated turnkey laser imaging systems based on application matched best selection of laser and camera

complete hardware control using DaVis software

accurate hardware and signal calibration

predefined crank angle resolved measurements with cycle statistics

multi-functional engine synchronization interface:

crank angle decoder, engine simulator, trigger conditioner

Specials

endoscopes for keyhole imaging

high speed digital film recording of complete cycles

high speed imaging pyrometers

EngineMaster Sychronizer for injection, ignition control and others

EngineMaster inspex

The EngineMaster inspex product range has been designed to provide turnkey solutions for in-cylinder spray and combustion visualization. The systems include all necessary components: high resolution digital color cameras with imaging endoscope, endoscopic spray and background contour illumination, engine sealing inserts, synchronisation electronics and software for recording and visualization. Three different options are available providing different levels of performance up to fully crank angle resolved high speed imaging.

Applications

spray visualization: propagation, geometry, wall interaction (wetting)

on-set of ignition, misfire, flame propagation

combustion visualization

detection of soot formation sources, e.g. pool fire

System Features

direct visualization of in-cylinder combustion cycle

full engine synchronisation with advanced triggering features

crank angle synchronized recording (standard)

crank angle resolved multiple cycle recording (high speed)

minimally invasive endoscopic illumination and imaging

high transmission endoscopes

high resolution digital color cameras

engine adaptation including engine sealing sleeves

Endoscopic Imaging

Endoscopic Imaging is commonly used in flow field and combustion measurement for gas turbines, IC-engines and industrial processes.

IC-Engines

cylinder internal flow field

swirl and tumble

combustion monitoring

fuel distribution with LIF

air-fuel ratio with FARLIF

Gas turbines

flame structure

flame front diagnostics via OH self emission or OH-LIF

flow field

flame vibration analysis

Industrial Processes

mixing

spray drying

particle combustion

heat exchangers

————————————————————————————————————————————————————

ParticleMaster

LaVision's ParticleMaster system family is designed to simultaneously determine size and velocity of individual particles or droplets in fluids or multiphase flows. The imaging systems analyze various types of particle laden fluids and other two-phase flows with high spatial resolution. Data acquisition and on-line evaluation are performed with the versatile DaVis software.

Applications

investigation of droplet or particle size distributions in various applications such as spray atomization, bubbles, particle flows ... for more details see Applications for Particle Imaging

Information

simultaneous size, velocity and position of individual particles

velocity-size correlations

morphology and shape information

mass flux and number density

ensemble statistics, frequency plots and histograms

visualization of ligament formation, spray break-up and atomization

System Features

integrated turnkey particle imaging systems matching optimal selection of illumination and detection devices

complete hardware control and timing with versatile DaVis software

accurate hardware and size calibration

comprehensive on-line image evaluation and data processing

most accurate evaluation algorithms

hardware compatible with LaVision's PIV systems

Specials

high speed image recording to investigate transient processes

high efficient diffuser for speckle-free illumination

——————————————————————————————————————————————————

SprayMaster

LaVision's SprayMaster is a complete family of optical measurement systems designed for non-intrusive analysis of spray processes in many fields. Various applications require different system approaches: LaVision is offering predefined systems (see overview) and special customized systems to achieve the application-specific performance. The systems are easy to operate, fast and efficient measurement tools for R&D as well as quality control.

Applications

imaging of sprays and related processes:

fuel injectors, spray coating and drying processes

pharmaceutical, medical and paint spraysspray patternation

cone angle

mass distribution

Sauter Mean Diameter D32

evaporation

... for further information see Applications in Sprays

System Features

integrated and modular spray imaging systems based on

application matched best selection of light source and

camera systemcomplete hardware control using DaVis software

accurate hardware and signal calibration

robust system designs for industrial spray inspection applications

customized test protocols

Specials

fiber optics light delivery systems

simultaneous multi-parameter spray imaging:

droplet size, temperature, velocity and phase information

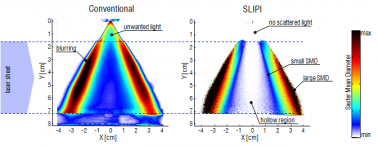

Quantitative Planar Droplet Sizing in Sprays

Since early 2000 LaVision provides a technique to measure the spatial distribution of averaged droplet size in a spray. The planar droplet sizing approach based on Laser Imaging produces 2D-resolved maps of Sauter Mean Diameter (D32) from spray images. Complementary to a pointwise measuring Phase Doppler Interferometer (PDI) the D32 technique reveals only averaged relative values, but instantaneously from a full plane.

Applications

fuel injectors (gasoline direct injection, Diesel)

gas turbines

spray cooling

pulsed and continuously running atomizers and spray nozzles

The planar droplet sizing technique uses Laser Induced Fluorescence (LIF) and Mie scattering, recorded at the same time. The 2-dimensional D32-maps are generated from the ratio of both signals. This technique is well-known, but tends to suffer from multiple scattering of the laser light within the spray cone.

Structured illumination with SLIPI improves spray imaging

LaVision now provides the improved SLIPI method using structured laser illumination, which overcomes the limitation from multiple light scattering and cleans up the images by removing image artifacts. 2-dimensional spray density and size maps will reveal the undistorted spatial structure with unsurpassed quality. The hollow cone spray shown in the picture now appears hollow, and the droplet size map matches well with pointwise recorded Phase Doppler data (PDI).

2-dimensional Sauter Mean Diameter (D32) map of a hollow cone spray with conventional imaging (left) and from cleaned up images with SLIPI (right).

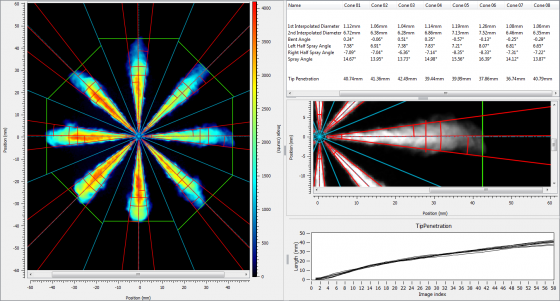

Spray Plume and Pattern Geometry Analysis

LaVision’s SprayMaster Geometry package extracts spray plume morphology and geometry information from backlight and light sheet spray images. It replaces conventional patternation by an optical measurement.

Depending on the optical arrangement, the LaVision SprayMaster system obtains information about the spray plume shape and propagation (axial spray cuts) or the plume pattern (radial cuts). Analysis of multi-hole injectors (e.g. automotive fuel sprays) reveals geometry information from each individual spray cone separately.

Axial spray cuts: plume geometry and propagation

Multi-hole injectors

For Diesel injectors and multi-hole gasoline injectors it is necessary to get detailed information about the stability and uniformity of each single spray cone. The Geometry of each cone is processed individually to present information about the uniformity of the spray formation. Time resolved measurements of individual spray strokes allow to measure the shot-to-shot stability in time.

SprayMaster Geometry dialog

The SprayMaster Geometry package allows to arrange results presentations defined by the operator. Multiple windows can be arranged together in a view according to individual needs. If more space is needed on the screen, information can be spread overmultiple tabs. Integrated screenshots and movie generation allow to achieve reportable results with a minimum of user interaction. Multi-threading and multi-processor support drastically increases the computation speed. Changes made to the processing parameters are shown in real-time to give instant feedback to the operator.

————————————————————————————————————————————————————

StrainMaster

StrainMaster 2D/3D DIC

StrainMaster from LaVision is a state-of-the-art, non-intrusive optical tool for shape, strain and deformation analysis of solid, granular and liquid subjects. StrainMastercombines the most advanced Digital Image Correlation(DIC) algorithms with the highest quality hardware to provide a complete and easy to use device for materials analysis. StrainMaster is applicable across all industries investigating material behaviour and gives fast, highly accurate results via an easy to use PC based interface.

StrainMaster can be supplied as a complete turn-key system or as stand alone software for importing and processing images from an external source such as a Scanning Electron Microscope (SEM). The system offers a complete solution and data management system able to drive hardware, acquire images, process data, validate, and display or export information.

During image acquisition the powerful StrainMaster system is able to command pulsed lighting, automate translation stage movement, record analogue load data and synchronise with external (e.g. cyclic) events. The user is able to set up batch operations for multiple processing steps, and utilise the resources of networked PCs via a distributed processing system; all of which is included as standard.

A range of StrainMaster systems are available from portable field work machines to highly specialised lab versions. Any system can be tailored to suit your particular requirements, e.g. for use with one camera for 2D and two cameras for stereo (3D) analysis or as high speed system , and are appropriate for both industrial and academic applications across a range of subject areas.

Several upgrades are available to make the StrainMastersystem capable of multi-parameter measurements. For example PIV can be added to measure fluid-structure interaction, by simultaneously measuring structure deformation and airflows.

StrainMaster DVC

LaVision's state-of-the-art Digital Volume Correlation (DVC) software brings new depth to quantitative imaging analysis.DVC is not only capable of identifying defects and cracks before they are visible in the raw image, but it is also able to quantify the full volume strain distribution and actual magnitudes of the material displacements surrounding discontinuities. The level of information is extremely useful in validating Finite Element models of modern complex materials. Volume images can be imported into the software from a variety of sources such as:

X-Ray Computed Tomography

Magnetic Resonance Imaging (MRI)

Optical Coherence Tomography (OCT)

Confocal Microscopy

————————————————————————————————————————————————————

LaVision's camera systems

| CCD and ICCD cameras are the heart of the laser imaging systems offered by LaVision. Therefore, LaVision is continuously striving to offer the most appropriate cameras for our customer's application. All camera systems include camera head, control units, multiport TTL-I/O interface, PC and high performance software DaVis for image acquisition, processing and analysis. LaVision's DaVis software allows complete camera function control, synchronization with other devices and peripheral device activation. All software functions are programmable via LaVision's command language (CL). CL allows the automization of complete measurement sequences including data acquisition and processing up to final result presentation and peripheral device control. Application specific software modules are available. |

diesel spray injection | |

| High-speed imaging provides detailed insight into transient phenomena. LaVision offers a range of digital (ultra) high-speed cameras and light sources operating together under advanced synchronization concepts. High-speed imaging is under complete software control for device operation, image acquisition, processing and presentation. |

exposure time: 1µs, frame rate: 67 kHz |

——————————————————————————————————

DaVis - The Complete Software for Intelligent Imaging Applications

DaVis is the complete software for intelligent (laser) imaging applications for non-reactive and reactive flow fields, material surface imaging and tracking and (ultra) high speed imaging.

The software integration of the selected imaging system is achieved with flexible acquisition modes, customized DaVis software interfaces and application specific imaging packages.

DaVis features user selectable acquisition sequences with precise synchronization on ns-time scale of camera exposure, illumination and external event trigger. A huge range of imaging devices are under DaVis control.

The open nature of DaVis in combination with its macro programming language (CL-language) allows a fast adaptation of the imaging system to different measurement tasks ranging from sophisticated research to reliable industrial applications.

Flexible image acquisition modes, advanced image processing algorithms, intelligent storage and presentation of multi-dimensional image data as well as the software controlled operation of all implemented hardware are the key features of DaVis.

DaVis runs under Windows 7 (64 bit) and offers the familiar Windows interactive user interface. The online help in PDF manuals can be viewed with the preferred browser. LaVision's in-house software engineers continuously design new algorithms for processing and displaying acquired data and including new camera types, lasers and other hardware devices.

————————————————————————————————————————————————————

Sensor Systems

LaVision is offering optical sensor systems for the following applications: