公司简介

Spartanics headquarters成立于1963年,总部位于芝加哥郊区奥黑尔国际机场附近。从电路板到汽车饰件,从保险卡到金融卡和智能卡,从标签到光电子等等,高精度技术往往是加速全球生产过程中看不见的一手。

产品列表

Product Lines

。Laser Cutting Machines

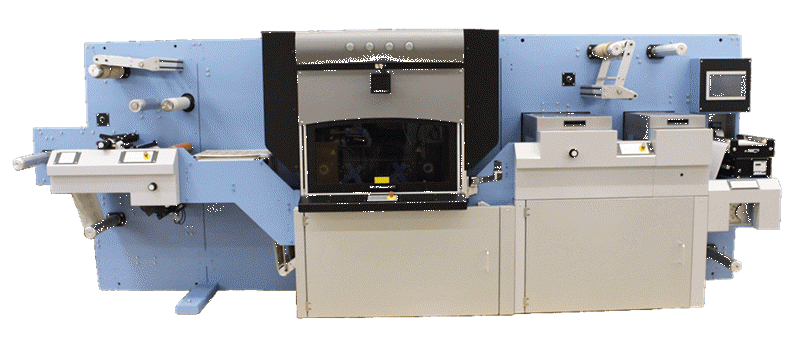

Introducing the Spartanics CS2000 Converting Machine. The CS2000 is a modular label finishing system that is integrated with Spartanics Fast-line AI plug-in die line creation software and Spartanics workflow application.

With the CS2000, converters are able to run roll-to-roll, roll-to-sheet or roll-to-part and can reconfigure or expand functionality as your needs change.

Converters looking for system flexibility can count on Spartanics to provide the most modular system on the market today.

MARKETS

Spartanics laser converting systems have provided many of our clients with opportunities to expand into new and existing markets, such as:

Labels

Stickers

Decals

Packaging

Medical Applications

Food and Beverage

Abrasive Materials

Direct Mail

Industrial

Automotive

Gaskets

CS2000 CONVERTING MACHINE OPTIONS

The following converting options can be integrated with the CS2000, add flexibility to your new or existing product lines, as well as, further enhance your label and packaging applications:

Unwind Module

Corona Treater

Web Cleaner

Laminator – Self Would Module

Laminator with Carrier Module

UV Varnish Station Module

Single Laser Cutting Module

Dual Laser Cutting Module

Semi-Rotary Diecutting Module

Backscore Slitter Module – Automatic

Backscore Slitter Module – Manual

Slitter Module – Manual

Rewind & Matrix Removal Module

Dual Rewind Module

Rotary Sheeter Module

Part Extraction Module

Web Accumulator Module

Turret Rewind Module

| CS2000 CONVERTING MACHINE | |

| Registration | X,Y |

| Material Cutting Area | 350 mm (13”) |

| Laser Power | 450 Watt |

| Laser Type | Sealed CO2 |

| Life of Laser | Recharge = 18,000+ Hours |

| Laser Beam Positioning | Galvanometer |

| Power | 338 V3 Phase 50/60 Hz |

Introducing the Spartanics Laser Lite Converting Machine. Laser Lite is a compact and affordable laser converting system integrated with Spartanics Fastline AI plug-in die line creation software and Spartanics workflow application.

Converters searching for an affordable and user friendly laser converting system, look no further! The Spartanics Laser Lite Machine comes standard with an unwinder, rewinder, scrap rewinder and laser die cutter that can cut unlimited label shapes. In addition, converters can benefit from additional add-on options, such as: web guide unit, self-wound laminate, a 250 Watt 10.2um CO2 laser high speed option, barcode reading and knife slitting.

MARKETS

Spartanics laser converting systems have provided many of our clients with opportunities in new and existing markets, such as:

Labels

Stickers

Decals

Packaging

Medical Applications

Abrasive Materials

Direct Mail

Industrial

Automotive

Gaskets

LASER LITE CONVERTING MACHINE OPTIONS

The following converting options can be integrated with the Laser Lite, add flexibility to your new or existing product lines, as well as, further enhance your label and packaging applications:

Web Guide Unit

Self-Wound Laminate

250 Watt 10.2um CO2 Laser High Speed Option

Knife Slitting

Bar Code Reading

LASER LITE CONVERTING MACHINE | |

| Registration | X,Y |

| Maximum Web Speed | 20 m/minute (65 ft) |

| Material Cutting Area | 320 mm (12.6”) |

| Maximum Roll Diameter Unwind | 500 mm (19.6”) |

| Maximum Web Width | 340 mm (13.54”) |

| Standard Unwind Mandrel | 76 mm (3”) |

| Laser Power | 120 Watt 10.2um |

| Laser Type | Sealed CO2 |

| Life of Laser | Recharge = 18,000+ Hours |

| Laser Beam Positioning | Galvanometer |

| Power | 220 – 338 V3 Phase 50/60 Hz |

Label Laser Cutting Machine – L-Series

Spartanics laser cutting solutions have revolutionized the way that printers, converters, and printing application specialists run their business. The superiority of Spartanics laser cutting systems are based on the sophisticated quality and depth control of software; tuned to handle the complexity of laser cutting behind the scenes and ultimately making an operator’s job minimal.

BENEFITS OF LABEL LASER CUTTING SYSTEMS

The Spartanics L-Series offers best-in-class laser cutting systems for 210mm and 350mm. Depending on the cut configuration, the speeds of the L-Series Laser Cutting Machines can reach up to 100+ meters per minute. Some of the other benefits include:

The 400W Laser

X,Y Registration

210 Micron Laser Spot Size

350 mm Wide Web Width

On the Fly Changeover

Fully customizable

Run multiple jobs in a single run

Runs as roll to roll or roll to sheet

Optional catch bin or constant height table

Variable sheet length

Spartanics optimization workflow software

User-friendly interface

LABEL LASER CUTTING APPLICATIONS

A standard 400W laser system with a single source scan head design meets most digital printing applications. Slitting, lamination, UV varnish, hot stamping, and rotary sheeting options are available with the L-Series Laser Cutting Machines. Some of the common applications include:

Labels

Adhesive Tape

Decals

Abrasives

Direct Mail

Industrial

Gaskets

MARKETS

Spartanics laser converting systems have provided many of our clients with opportunities in new and existing markets, such as:

Labeling

Packaging

Medical Applications

Abrasive Materials

Direct Mail

Industrial

Automotive

Wine

Beauty

Food & Beverage

LABEL LASER CUTTING MACHINE CONFIGURATIONS

Roll Fed

Sheet Fed

Combination Roll/Sheet

Roll to Sheet

Roll to Roll

Roll to Part

LABEL LASER CUTTING MACHINE OPTIONS

Spartanics is able to customize laser cutting systems with add-on converting options of your choice. The following converting options can add flexibility to your new or existing production lines, as well as, further enhance your label and packaging applications:

500 mm Wide Option

350 mm Wide Option

210 mm Wide Option

UV Coating System

Rotary Die Cutting Station

Rotary Sheeting Option

Rotary Hot Stamper

Knife Slitting Component

Rotary Knife Slitting Component

Lamination Device

Bar Code Reading

MATERIALS USED FOR LABEL LASER CUTTING

Common materials used for the label laser cutting machines include plastic, polyester, fabrics, paper based, metals, and composites.

For more information on the available converting options for the L-Series Label Converting Machine, click here.

| LABEL LASER CUTTING MACHINE SPECIFICATIONS | |

| Registration | X,Y |

| Maximum Web Speed | 100+ m/minute |

| Material Cutting Area | 500 mm Wide350 mm Wide210 mm Wide |

| Maximum Web Width | Up to 600 mm Wide |

| Maximum Roll Diameter Unwind | Up to 1000 mm Wide |

| Maximum Roll Diameter Rewind | Up to 1000 mm Wide |

| Laser Spot Size | 210 Micron |

| Laser Power | 400 W |

| Laser Type | Sealed CO2 |

| Laser Power Consumption | 24 KWh |

| Life of Laser | Recharge = 18,000 Hours |

| Laser Beam Positioning | Galvanometter |

| Power | 220 – 338 V3 Phase 50/60 Hz |

Dual Laser Cutting Machine – L-Series

The Spartanics Dual Laser Cutting Machines are designed to laser cut rolls or sheets of material for the label, packaging, carton board and abrasive industries. This dual laser cutting solution was designed specifically for wide format printers with material capabilities of up to 500-600 mm wide; eliminating the need for physical dies. Developed as a dual-head finishing solution, the L-Series Dual Laser Cutting Machine comes standard with 2 – 400 Watt laser heads and incorporates Spartanics best-in-class laser control software for the best quality and highest throughput speeds in the industry.

MARKETS

Spartanics Dual Laser Cutting Machines have proven to be greatly beneficial for the industries of wide format printers and converters that are currently serving the following markets:

Labels

Packaging

Carton Board

Abrasive Materials

Industrial

Wide Format Printers

Direct Mail

Gaskets

DUAL LASER CUTTING MACHINE SPECIFICATIONS

Roll-to-Roll Digital Cutting Machine

Unwind Modules up to 600 mm diameter rolls (1000 mm diameter available)

Rewind Modules up to 600 mm diameter rolls (1000 mm diameter available)

Scrap Modules up to 500 mm wide

Web Steering Device

210 Micron Laser Spot Size

500 mm Cutting Field

XY Registration

Up to 100+m per minute

Applications Software – Optimization, Cut-And-Stitch, Estimator

DUAL LASER CUTTING MACHINE CONFIGURATIONS

Roll Fed

Sheet Fed

Combination Roll/Sheet

Roll to Sheet

Roll to Roll

DUAL LASER CUTTING MACHINE CONVERTING OPTIONS

The Dual Laser Cutting Machine has the flexibility to be customized with several different converting options to enhance your products and provide efficiency to your production line. Some of the converting options that are available for the Dual Laser Cutting Machine are:

UV Coating System

Rotary Die Cutting Station

Rotary Sheeting Option

Rotary Hot Stamper

Knife Slitting Component

Rotary Knife Slitting Component

Lamination Station

Bar Code Reading

Roll Fed Laser Converting Machine – R-Series

The Spartanics Roll Laser Converting Machines are custom laser cutting machines that are designed to work seamlessly with all applications. Roll Laser Converting Machines can be configured as roll-to-roll, roll-to-sheet systems or a combination of roll/sheet. Roll fed laser cutting systems are ideal for label converters that handle printed label rolls. These rolls of labels often contain multiple jobs and can be easily cut without stopping production in between jobs with Spartanics barcode reading software capabilities.

The Roll Laser Converting Machine allows manufacturers the freedom to add or remove components based on the complexity of their operations. Each of our laser cutting systems are designed to add-on converting options, such as: Laminators, UV Coaters, Slitters, Sheeters, Rewinders, Part Extractors, etc. To learn more about the types of available converting options for Spartanics Roll Laser Converting Machines, please click here. Below are examples of different types of Roll Laser Converting Machines with an infinite amount of capabilities.

MARKETS

Spartanics Roll Laser Converting Machines are the most popular amongst our clients and are present in a variety of industries, including, but not limited to:

RFID

Automotive

Abrasive Materials

Membrane Switches

Flexible Circuitry

Gaskets

Magnets

Industrial

Direct Mail

ROLL LASER CONVERTING SYSTEM CONFIGURATIONS

Speeds from 60 m to 100 m per Minute

210 Micron Laser Spot Size

Applications Software – Optimization, Cut-And-Stitch, Estimator

ROLL LASER CONVERTING MACHINE OPTIONS

The Roll Laser Converting Machine can be customized with converting options of your choice to further enhance your production line. Converting options available for the Spartanics roll fed laser cutting machines include:

500 mm Wide Option

350 mm Wide Option

210 mm Wide Option

UV Coating System

Rotary Die Cutting Station

Rotary Sheeting Option

Rotary Hot Stamper

Knife Slitting Component

Rotary Knife Slitting Component

Lamination Station

Bar Code Reading

For a more detail list of available converting options, visit the Laser Converting Options Page.

BENEFITS OF ROLL-FED LASER CONVERTING

Roll-fed laser converting systems by Spartanics provide label converters with the highest quality cuts, seamless job integration and efficient workflow automation through the use of Spartanics Laser Software Technology and state-of-the art engineering. Additional benefits include:

Increased Productivity

Defect-free Cutting

Tool-free Cutting

Eliminate Layout Limitations

Reduced Scrap Material Costs

Reload Jobs in Minutes

Consistent and Repeatable Cut-to-Print Registration

ROLL AND SHEET FED LASER CUTTING MACHINE

With this hybrid roll and sheet-fed laser cutting machine, your company can provide the most versatile cutting solutions in the market today. This system enables you to make any combination of cutting and marking details; allowing you to seize every job opportunity that comes your way.

With this hybrid roll and sheet-fed laser cutting machine, your company can provide the most versatile cutting solutions in the market today. This system enables you to make any combination of cutting and marking details; allowing you to seize every job opportunity that comes your way.

SYSTEM CONFIGURATIONS

• Speeds up to 100 m per minute

• Cutting areas up to 350 mm for a single source laser

• Cutting areas up to 50 mm for a dual head laser system

ROTARY AND LASER CUTTING MACHINE

Spartanics offers the world’s most accurate single source laser die cutting systems. The Combination Laser Die Cutting and Rotary Die Cutting Machine is automatically optimized to cut at the fastest web speeds possible. This system is interchangeable with traditional rotary die cutting and offers a range of optional add-ons.

Spartanics offers the world’s most accurate single source laser die cutting systems. The Combination Laser Die Cutting and Rotary Die Cutting Machine is automatically optimized to cut at the fastest web speeds possible. This system is interchangeable with traditional rotary die cutting and offers a range of optional add-ons.

SYSTEM CONFIGURATIONS

• Rotary die cutting speeds up to 300 m per minute

• Laser cutting speeds up to 100 m per minute

SRL350 – Semi-Rotary Laser Converting Solution

The superiority of the Spartanics’ laser converting equipment is based on the sophisticated quality and depth control software for laser cutting and finely tuned servo motion control systems for conventional finishing. Manufacturer’s world-wide are now able to maximize their profits by offering their clients flexibility in real world market situations. With the Spartanics SRL350, you can seamlessly convert short and long run jobs while minimizing waste and job turn over times.

Not interested in incorporating laser into your production? Check out the base model, SR350 Semi-Rotary Converting Solution.

MARKETS

The SRL350 Semi Rotary Laser Converting System provides flawless results and products that can be supplied to a number of today’s markets, including:

Labels

Packaging

Decals

Industrial

Health & Beauty

Food & Beverage

Automotive

Pharmaceutical

SRL350 SEMI-ROTARY CONVERTING OPTIONS

The SRL350 Semi Rotary Laser Converting System is able to be integrated with the most popular converting options available in today’s industry.

200W, 400W or 1000W Laser

Single or Dual Laser Source Options

Parts Extraction Available

On-the-Fly Job Changeover Software

Semi-Rotary Device

Varnish Station

Lamination Device

Sheeter

Back Scoring Slitter

SRL350 SEMI-ROTARY LASER CONVERTING SYSTEM SPECIFICATIONS | |

| Unwinder Max Web Width | 13.78″ |

| Unwinder Max Roll Diameter | 31.4″ |

| Rewinder Max Web Width | 13.78″ |

| Rewinder Max Roll Diameter | 31.4″ |

| Waste Rewind Max Roll Diameter | 19.69″ |

| System Registration | +/- 0.006″ |

SRL350 CONVERTING OPTION CONFIGURATIONS | |

| Laser Die Cutting Module | 200W or 400W Sealed Co2 |

| Laser Running Speeds | 200W 30m per minute, 400W 60m per minute |

| Semi-Rotary Die Cutting | 19″ Cylinder, 4″-18″ Repeat |

| Semi-Rotary Die Cutting Speed | Up to 80+ m/min *High Speed Option Available |

| Varnish Station | Flood Coating – UV/Aqueous |

| Laminator | Self Wound or Laminate w/Liner |

| Back Scoring Slitter | Stationary Blades |

| Sheeter – Servo Controlled | Programmable Sheet Length |

| Rewind Module | Single or Dual |

In-Line Laser Cutting Machine

The Spartanics Laser Die Cutting Station can be built into your current assembly chassis or print lines; such as: Digital, Screen, Offset, etc. Your current production line can benefit from defect-free and tool-free cutting with our laser cutting system integration. Just like all of Spartanics laser cutting machines, this system can be customized to suit your manufacturing needs.

Spartanics Laser Die Cutting Station can be engineered to fit various widths, such as 140 mm as found in the NW140 UV Inkjet Digital Printing Press and 210 mm width as found in the the NW210 UV Inkjet Digital Printing Press. Spartanics 350 mm wide laser cutting stations have also been integrated into laser finishing solutions, such as the Durst LFS 330 Laser Finishing System.

MARKETS

Laser cutting has proven to be beneficial to many industries. Our laser cutting systems have created new opportunities for many of our clients in new and existing markets, such as:

Label

Packaging

Plastics Decoration

Card

Flexible Solar Panels

Membrane Switches

Flexible Circuits

Electronics

Aerospace

Metal Parts

RFID

POP Displays

Signage

Textiles

Automotive

Medical

Gaskets

Direct Mail

LASER DIE CUTTING STATION SPECIFICATIONS

Speeds up to 100 m per Minute

210 Micron Laser Spot Size

Cutting Areas up to 600 mm

LASER DIE CUTTING CONFIGURATIONS

Roll Fed

Sheet Fed

Combination Roll/Sheet

Roll to Sheet

Roll to Roll

LASER DIE CUTTING STATION OPTIONS

With converting options, you can achieve added efficiency and flexibility in your current production line. Converting options available for the Spartanics Laser Die Cutting Station include:

140 mm Wide Option

210 mm Wide Option

350 mm Wide Option

Barcode Reading

Laser Cutting Machine Options

Spartanics is able to customize your laser cutting machine with options that are suited for your specific applications. Please read below to learn about some of the most common add-on features that Spartanics has to offer.

UV COATING SYSTEM | The varnish station is used to enhance the look of a label and/or increase the durability. Flood coating (complete coverage) or spot coating (specific areas) are possible options for UV coating stations |

ROTARY DIE CUTTING STATION | The rotary die cutting station offers flexibility for customers that require longer job runs on their digital printing lines or flexo presses. Magnetic dies attach to a rotary cylinder within minutes for quick changeover. The use of rotary die equipment has been a staple in many label, textile and adhesive tape manufacturing operations for years due to overall speed and relative flexibility. A full cylinder rotary die cutter uses a cylinder that holds a die plate for making an impression during each revolution. The problem with shorter runs is there is no flexibility for changing the size of the step and repeat. In order to change the step-and-repeat you need a completely different cylinder which can be expensive. Semi-rotary die cutting cylinders controlled by servo motors are also available. The cylinder and substrate react in tandem to provide a lot of flexibility in terms of part layouts and step ups. A full cylinder rotary die makes for a difficult changeover when removing a full 25” wide cylinder that can weigh 400 lbs. A 25” full rotary die cylinder requires every print job to have the same step and repeat of approximately 23”. A 25” semi-rotary cylinder gives the user the ability to run, for example, a 12” step up therefore providing more reasonable die costs and much more flexibility on shorter run jobs. |

ROTARY SHEETING OPTION | The rotary sheeting option takes a roll of printed/laser cut labels and converts these labels into sheets. A rotary cylinder is designed with cutting blades across the width of the cylinder to cut the roll of material into sheets each revolution. Most designs require a semi-rotary cylinder that has the flexibility to cut a variety of sheet lengths determined by the job requirement. The sheet can then be placed in a catch bin or a motorized stacker for further processing. |

ROTARY HOT STAMPER | This option is used to enhance the look of a particular label. A heated platen and pressure are used to press down the foil material onto a given substrate (media) to make the label look more elegant. The foil is positioned above the material and imprinted allowing the combination of heat, dwell time, pressure and stripping time to control the quality of the stamp. An example would be a wine label with an image of rolling hills and a thin foil border to enhance the overall appearance. |

KNIFE SLITTING COMPONENT | Provides a cheap alternative for slitting with stationary knife blades. These blades are manually positioned using set screws for distance and depth of cut. Slitting is used to take a 350mm wide roll of material that has been printed with multiple jobs and create separate label job rolls. For example, the customer prints two rows of labels and the slitting device cuts through the 350mm wide web to make two 175mm rolls. The separate rolls then rewind on a spindle (or separate spindles) and are removed by the operator. |

ROTARY KNIFE SLITTING COMPONENT | This option provides a more expensive alternative for slitting using adjustable rotary blades against an anvil for slitting rolls. Rotary slitting blades can be manually positioned using set screws for distance and depth of cut or automatically controlled through the operator interface. Slitting is used to take a 350mm wide roll of material that has been printed with multiple jobs and create separate label job rolls. For example, the customer prints two rows of labels and the slitting device cuts through the 350mm wide web to make two 175mm rolls. The separate rolls then rewind on a spindle (or separate spindles) and are removed by the operator. |

LAMINATION COMPONENT | Lamination provides a protective coating on the top or bottom of the finished label substrate. This option may enhance the look of a label and also provides more durability than the UV coating option. Single-sided, double-sided (top and bottom) lamination options are available. This component may require multiple rewinds for backer liner removal or it may simply apply a top layer of protection with or without a removing a liner. |

BARCODE READING | Barcode reading allows automatic changeover. With this option, the machine will be capable of running multiple jobs in one run, change cut configurations on the fly and can provide automatic database integration for total parts traceability. |

XY REGISTRATION | Spartanics optical print XY registration and camera systems can sense anything by contrast or shape. |