公司简介

The Company started off with the manufacture of opthalmic lenses and amateur quality telescopes.

With the gradual acquiring of expertise, the company shifted its focus to precision optics and opto-mechanical assemblies.

During the past 35 years of growing from a small beginning, the Company established manufacturing facilities for precision optics, imported from world renowned manufacturers. Variety of optical test equipments were also imported from time to time to scale up the inspection capabilities for precision optics.

产品列表

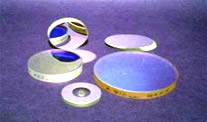

OPTICS

| Materials with which we have worked | Type of products we make |

| Lenses Windows Prisms Mirrors Beamsplitters Filters Optical Flats Laser Optics Optical Assemblies Special Optics |

LENSES

| We make all kinds of lenses up to Ø200mm. Also available with anti-reflection coatings. Lenses can be also be mounted as required. |

WINDOWS

| Windows are optical elements having where both the surfaces are plane in nature. We can manufacture windows up to 200mm in size. Windows can be coated with anti-reflection coating which increases the transmission. They can be of general grade, just being optically polished or precision grade, with control on the parallelism and flatness. We can manufacture windows with parallelism of less than 5 seconds between the surfaces and with flatness up to lambda/10 depending on the size and thickness. We also supply windows as thin as 0.1mm. |  |

PRISMS

Click here for detailed description | Prisms play an important part in any optical system. Their main function is to deviate the beam of light in a different direction. They also considerably shorten the light path of an optical system and can invert and revert images, the reason for their being used in binoculars. They can break up the light into its constituent colors. They are available with anti-reflection coatings as well as other coatings as required. Prisms can be made to high degrees of angular accuracy. |

MIRRORS

| Mirrors are used for reflecting the light in optical systems. They are can be designed for either normal or oblique angles of incidence and can be partial reflectors or high reflectors. They can have one curved surface or both plane surfaces also. Telescope mirrors are examples of aluminum coated mirrors. Dielectric coated mirrors can be used with lasers and a variety of applications. |  |

BEAM SPLITTERS

| Beam splitters partially reflect / transmit the incident light. They are normally used at 45 degrees incidence. They split the laser beam in required R/T ratio. They can either be in plate form (like a window) or in cube form. Cube beam splitters have two right angled prisms of similar material cemented together. One of the prisms has the beam splitter coating on its hypotenuse. |

FILTERS

| Click here for detailed description | Filters are used to "filter" out light, i.e. to separate out wavelengths. They can be similar to windows in size and shape. We manufacture filters of various types. |

OPTICAL FLATS

| We make Optical flats up to lambda/10 accuracy from Pyrex or Fused Silica. |  |

LASER OPTICS

| We can manufacture laser optics with high damage threshold coatings as per customers requirements. |

OPTICAL ASSEMBLIES

| Optical assemblies are an integral part of any optical system. We have a fully equipped metal working shop including a CNC lathe machine from Hardinge, USA to give all kinds of optical mountings for our optics. We can make assemblies as per your specifications. Assemblies are done on Class 100 workstations in Class 10,000 clean room. |

SPECIAL OPTICS

Apart from all the above listed optics, there are many other things that we have worked on which do not fall under any standard category. Some of them are as follows:

Silicon Carbide substrates - Grinding and polishing of silicon carbide to a high degree of flatness and surface finish.

Cuvettes - We supply special cuvettes for use in milk meters. These have 2 components made from Pyrex. The tolerances on the thickness and the parallelism are 4-6 microns. One of the component also has precision drilled holes. We also supply 10 micron depth cuvettes for use in analytical instruments.

Quartz Wafers - We have successfully supplied 0.1 mm thick quartz wafers.

Domes - We have made quartz domes for radiometers.

Acrylic window polishing.

Photomask substrates.

Metal polishing.

THIN FILM COATINGS

Thin film coatings play a very important part in any optical system. An uncoated glass surface will reflect or transmit a percentage of the light depending on its refractive index and the angle of incidence.

Thin film coatings change the amount of light reflected or transmitted through the optics. These are very thin layers (of the order of Angstroms) of materials coated on to the substrate, hence the term "Thin Films". These can be single layers or multiple layers coated on top of one another to achieve the required reflection / transmission. Oxides, Fluorides, metals are used for this purpose. The evaporation has to be carried out in special coating machines developed for this purpose and under high vacuum.

The whole process of coating is quite complicated and requires continual development. The coatings are designed using special software and then stabilized on the coating machine to get performance as per the design.

Astro Optics has a two "box coater" units from Leybold, Germany, equipped with turbo molecular pump, e-beam evaporator, thermal evaporator, radiation heaters and Ion source. Starting with coating designs and processes purchased from Leybold in 1988, we have learnt and developed all coatings in-house over the years. We design our coatings using "Essential Macleod" from Thin Film Center, USA. With years of experience in this field, we have a vast range of coatings, mainly developed as per customer requirements. All the coatings are checked for performance on our Perkin Elmer spectrophotometers.

We are able to do coatings in the wavelength range 190-2500nm. Our coatings can withstand adhesion / abrasion tests as per MIL 675C / MIL 13830B. The cleaning of the optics prior to coating is done in Class 10,000 clean room area and the final checking and putting the pieces in the coating jigs is done on class 100 clean room tables. Each piece is individually inspected for defects prior to coating.

TYPES OF THIN FILM COATINGS:

![]() Anti - reflection coatings

Anti - reflection coatings

All glass surfaces have some reflection depending on their refractive index. N-BK7 glass which is most widely used, has a refractive index of about 1.51 in the visible region of light, and reflects an average of 4.25% of the light incident on it. Materials with higher index reflect a greater percentage of light. Anti-reflection coatings (or ARC's) are used to reduce the reflection from the surface of the optics and thus increase the transmission. These coatings can be of single layer or multi-layer depending on the material to be coated and application.

Click here for detailed description.

![]() Reflective coatings

Reflective coatings

Some applications require the substrate to be coated so that large amount of the incident light or a specific amount is reflected. These are high reflection or partial reflection coatings. These can be either metal coated or dielectric coated.

Click here for detailed description.

![]() Beam splitter coatings

Beam splitter coatings

Beam splitters are used to split the incident beam in two parts. These are used at an oblique incidence, usually 45°. These can be designed for either of the two polarization states or for the mean polarization. The beam is split in required R / T ratio.