公司简介

Since 1959, Associated Environmental Systems has designed, manufactured, and supported standard and custom test chambers that meet our customers' most demanding requirements. Our products vary in size from small bench top test chambers to very large walk-in or drive in environmental rooms. AES robust test chambers simulate hot and cold temperature extremes and variations, humidity and moisture conditions, salt spray and thermal shock. While some companies rely on test labs to perform their testing, many companies realize the benefits of performing their own testing in-house. These benefits include: the flexibility to test according to their own schedule - even when it changes, the ability to optimize the type of testing that works best for them, and substantial time and cost savings.

产品列表

BD-0.5 | BD-01 | BD-02 | BD-04 |

BD-08 | BD-27 | BD-64 |

TEMPERATURE / HUMIDITY TEST CHAMBERS

Floor Test Chambers | Benchtop Test Chambers | Rack & Stack Test Chambers | Walk-In Test Chambers | Custom Test Chambers |

SM SERIES THERMAL SHOCK CHAMBERS

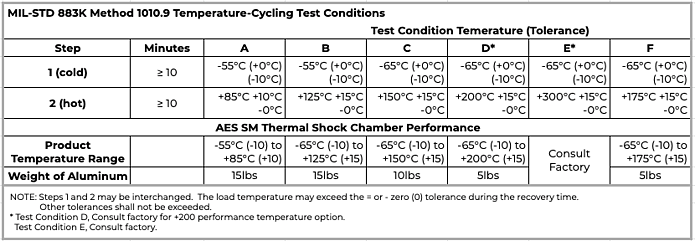

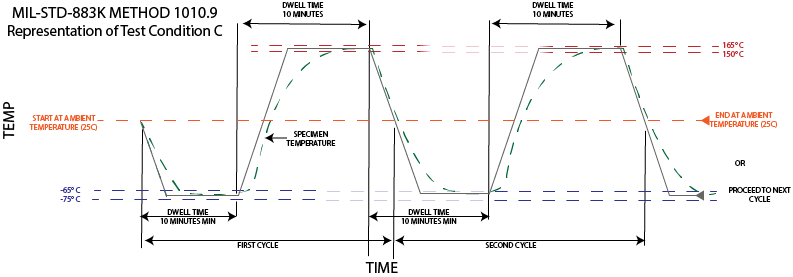

MIL-STD 883K Method 1010.9

MIL-STD 883K Method 1010.9

On the left, the table specifies the test conditions the SM Thermal Shock test chamber can achieve under the military and aerospace conditions to adhere to the uniform method for thermal shock testing of microelectronic devices within electronic systems. These devices include monolithic, multi-chip, film and hybrid microcircuits, microcircuit arrays, and the elements from which the circuits and arrays are formed.

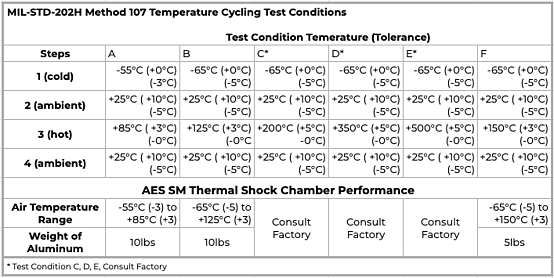

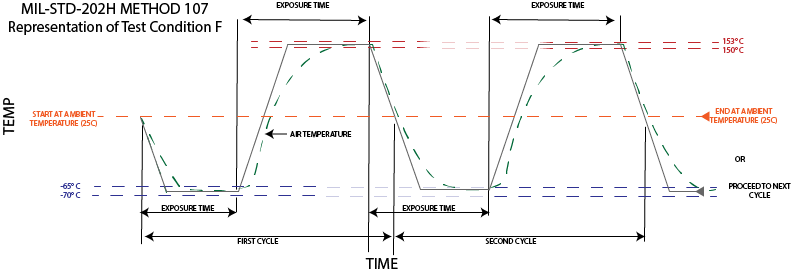

MIL-STD 202H Method 107

MIL-STD 202H Method 107

SM Thermal Shock test chambers are designed to meet Method 107 test conditions A, B, and F when testing electronic and electrical component parts such items as capacitors, resistors, switches, relays, transformers, inductors, and such at weights of 10 or 5 pounds, see table (left).

The test method should apply only to small component parts, weighing up to 300 pounds or having a root mean square test voltage up to 50,000 volts unless otherwise specified.

SM-02 | SM-05 | SM-08 |