公司简介

Gurley Precision Instruments (GPI) has been in business since 1845. We started in surveying instruments, where we were a global leader in both quality and precision, soon after introducing water current meters in the late 1800s, optical patterns on glass and test instrumentation in the early 1900s, and finally optical encoders in the 1950s, which is presently our largest product line. Our main office and factory reside in Troy, New York, however we have joint ventures in Russia, Lithuania, Slovenia, and China to support our various component and assembly needs.

产品列表

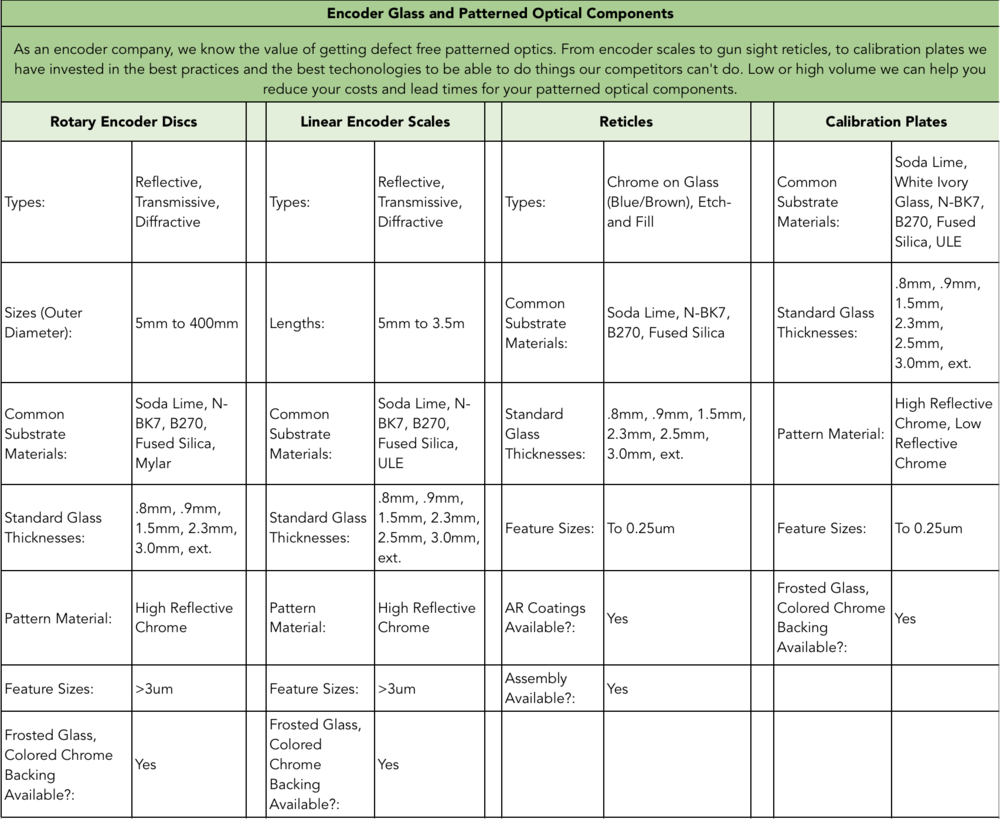

OPTOGRAPHICS

Optographics is the production of precision masters and the replication of these patterns in metallic depositions or photographic emulsions on various substrates. At Gurley Precision Instruments, we have taken Optographics from its infancy to the continuously expanding state of the art products we have today. Some of our more standardized Optographic products include:

Reticles, Resolution Targets (including USAF & Sayce), Gratings, Step Wedges, Optical Rulers Field Finders, Rapid Comparators, Encoder Discs & Scales, Apertures and Grids

Lovins Micro-Slide Field Finder and Rapid Comparator Datasheet and Pricing (.PDF File)

General capabilities include:

Precision master generation, both linear and rotary.

Substrate fabrication including shaping, drilling and grinding & polishing of glass, and cutting and hole punching of film.

High vacuum deposition of coatings.

Pattern replication from prototypes to high volume on flat, curved, or odd shaped surfaces.

Image contrast control and multiple image registration.

Assembly, including bonding of encoder discs to hubs and reticle, or scale mounting in holders.

Inspection to MIL-I-45208 specifications.

| Patterns vary from simple cross hairs and standard resolution targets to sophisticated sighting reticles and registration patterns for commercial, military or aerospace applications. Other than chrome, we vacuum deposit many other metals for reproducing patterns including nichrome, aluminum, silver, copper, inconel, titanium and gold. |

Substrate material is quite varied due to transmission requirements, coefficient of expansion, and other exotic demands. Besides soda-lime float glass, we use borosilicate crown glass, quartz, fused silica, zinc sulfide, zinc selenide, calcium fluoride, germanium, lithium niobate and sapphire to name a few.

Our vacuum coating area can apply special coatings such as magnesium fluoride, silicon monoxide, cerium fluoride and zinc sulfide for their anti-reflective properties, or for their ability to protect less durable coatings like aluminum, silver and gold.

Our years of experience and creative engineering staff give us the ability to tackle your most challenging optographic problems with a degree of success unequaled in the industry.

Your Disc and Scale Assembly Specialists

The quality, performance, and most importantly cost, of our discs and scales can help make your products more competitive. We currently supply these products to several international companies, including the semiconductor and instrumentation manufacturing industries.

Some of the benefits we can provide include:

lower material and labor costs

lower inventory levels

just-in-time (JIT) delivery

General Technical Specification for Gurley Discs and Scales:

OPTICAL

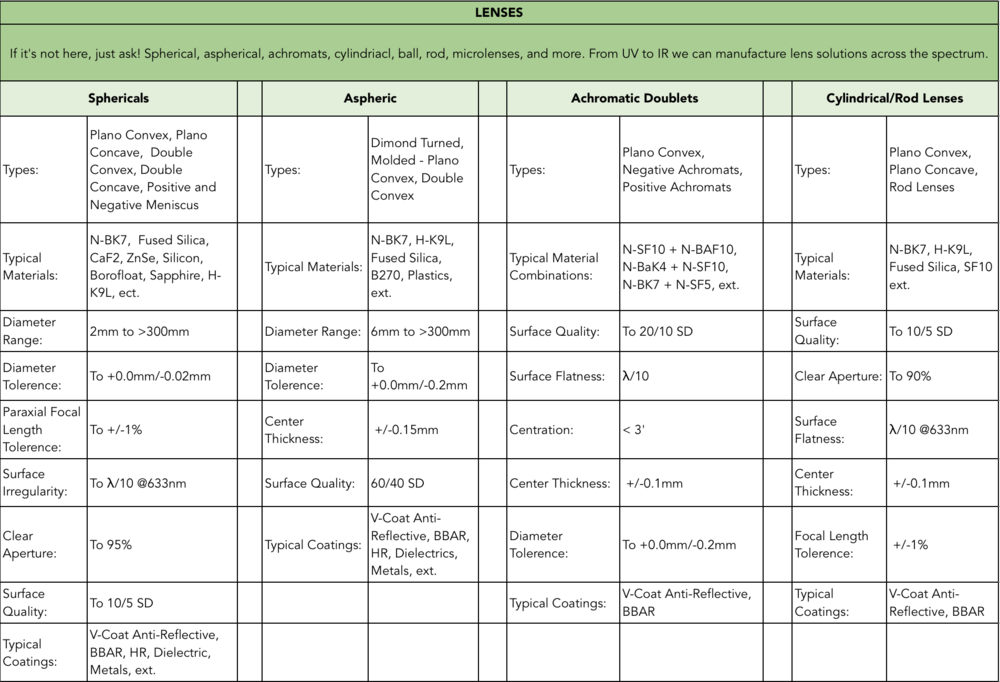

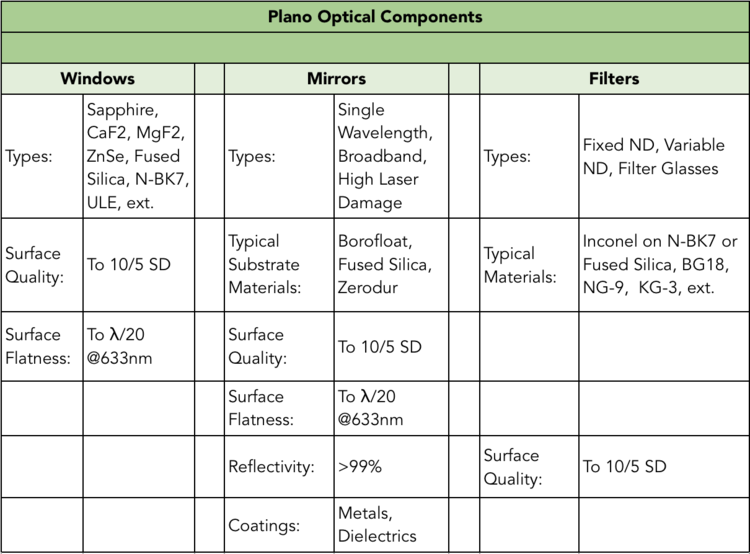

In addition to our Optographics capabilities, Gurley offers a wide variety of high quality optical materials and optical components, at prices that are second to none.

GPI has the ability to supply standard, precision and custom designed components that may be fabricated from fused silica, crystal quartz, optical crystals, acrylics and metals. With over 50 years experience in the optical industry, GPI has the knowledge, dedication and service you need to get the job done.

Gurley's Optics Division aims to be the lowest cost, high quality option for a number of different types of optical components. With US, European, and Asian manufacturing, we're able to make custom parts as well as duplicate off-the-shelf parts with the highest quality and lowest prices on the market.

US Quality Control for all parts

Vendor managed inventory

First Article Inspection Reports for all new parts

Just-in-time delivery

| Lenses - from several inches to a few millimeters in diameter Plano Convex, Plano Concave, Bi-Convex, Bi-Concave, Positive and Negative Meniscus, Achromatic Doublet & Triplet, Cylindrical, and Unique Camera Lenses |

Beam Splitters - polarized and unpolarizedBeamsplitter Plates and Cubes |  |

Mirrors - protected and unprotected coatings

Flat Aluminized, Maximum Reflection Flats, Front Surface Concave; Silver Plane, Front surface concave

Mirrors - protected and unprotected coatings

Flat Aluminized, Maximum Reflection Flats, Front Surface Concave; Silver Plane, Front surface concave

| Prisms Wedge, Brewster’s Angle Dispersing, Littrow Dispersing, 60° Equilateral Dispersing, Roof, Poro, Penta, Right Angle, Dove, Retro-Refelctor Prisms and Other Types |

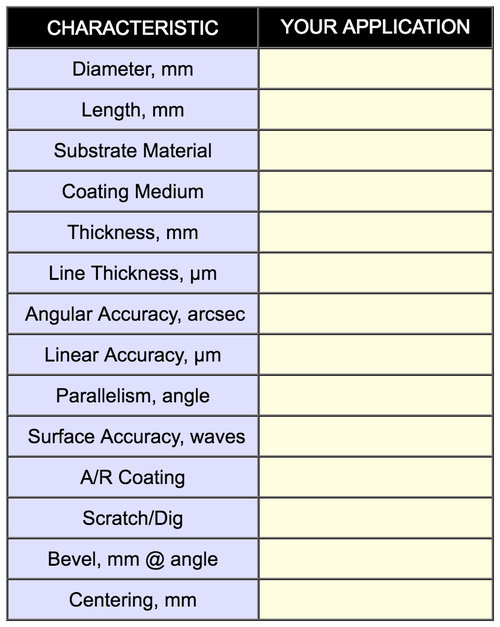

And More! Are we missing something? Let us know - we can design entire lens systems, specify materials or just lend a hand in your applications. Please use the following table as a reference when submitting a request for quotation or when reviewing a possible application.

|  |

OPTICAL COATINGS

Gurley Precision Instruments offers U.S. made standard and custom coatings at overseas prices. Our coating chambers and expert staff provide a variety of custom coatings to meet your specifications for Visible and Near IR applications. We specialize in offering custom designed coatings on our substrate or yours.

Features and capabilities include:

Large selection of design coatings

High durability and Laser damage threshold (Typical: 20J/cm2 -20ns pulse)

Anti-Reflective (AR): Single or multiple layer Magnesium Fluoride (MgF2 ); “vee” coats; broadband and dual range multi-layer coatings

Reflective Mirrors: Aluminum, Chrome, Inconel and Dielectric

Data Certification provided with every order

Coatings optimized to your custom requirements

![]()

Optical Coating Types and Specifications:

Anti-Reflection Coatings

NarrowBand AR Coating (Vee-Coat) Optimized for single wavelength (ie. 450nm, 550nm, 650nm). Typically R<0.10% at the customer’s specified visible region wavelength (non-absorbing, high efficiency for high laser damage threshold)

NarrowBand AR Coating with SiO2 (Vee-Coat) Optimized for single wavelength, an SiO2 coating protects the AR coating. Typically R<2% at the customer’s specified visible region wavelength (non-absorbing, high efficiency for high laser damage threshold)

Broadband AR Coating Broadband AR coating for the visible photonic region. Typical R<0.5% between 450 to 700nm.

Low Cost Broadband AR Coating Broadband AR coating for the visible photonic region but reflectance spec is loosened to R<1.0% between 450 to 700nm. Because of the higher reflection specification, this is a lower cost alternative.

Reflective and Dielectric Mirror Coatings

Protected Aluminum Coating Aluminum with SiO2 protective overcoat. R> 88% 450-700nm. Other configurations to your specific requirements are available.

Enhanced Aluminum Coating Aluminum overcoat with multiple protective coatings. Typical reflectivity to 95% in the visible range of 450 to 700nm. Call with your specifications.

Dielectric Mirror Coating GPI offers dielectric coating capabilities for various wavelength and light regions designed for your requirements (ie. R>= 99.9% @1550-1650nm).

Other Coatings

In addition to the above product capabilities, we also provide the following: Double Wavelength AR Coatings, Beamsplitters, Dichroic Mirrors, Neutral Density Filter Coatings, patterned images and other custom designs per your specifications.