公司简介

For more than 15 years, Lambda Research Optics, Inc. has been a leading manufacturer of laser optics with high power thin film coatings and high precision fabrications. Lambda serves a wide range of industries, such as Biotech, Semi-conductor, Industrial, Defense & Security, and many more.

Lambda Research Optics, Inc. is a manufacturer of catalog and custom lenses, mirrors, beamsplitters, windows, prisms, filters, polarizers for defense, commercial, and medical laser applications. Lambda specializes in high-power coatings for Excimer, YAG, Fiber, CO2 lasers, and FLIR coatings. Lambda has precisionpolishing of CaF2, MgF2, BK7, Fused Silica, ZnSe, Ge, and Si. Complete prototype to production quantities can be provided.

产品列表

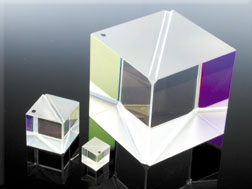

BEAMSPLITTER CUBES | METALLIC COATED MIR… | ||

WAVEPLATES WAVEPLATES |  CYLINDRICAL LENSES CYLINDRICAL LENSES |  ND:YAG OPTICS ND:YAG OPTICS |

NEW PRODUCT

BEAM EXPANDER

2x-8x Magnification for Nd:YAG Applications

Lambda, in its 15 years of business, is committed to producing innovative optical products for customers at reasonable prices. Lambda continues this tradition with VHBX.

Beam expanders are telescopes in which a laser beam is expanded to a larger diameter. This can be useful to illuminate a larger area or to reduce the divergence of the beam.

Benefits of VHBX

Non-rotational (translational) Zoom system. Optical axis is always aligned

Fundamental, second and third harmonics (1064nm, 532nm, 355nm)

Suitable for high power applications

Specifications

V type AR at wavelength of use. Total Transmission > 97%

Surface Quality: 10/5 both sides

Damage Threshold : > 5 J / cm², 10ns @ 1064nm

Housing : Black anodized Aluminum

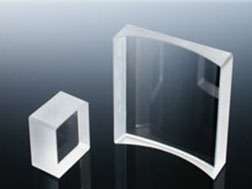

VELO FOCUSING LENS

VeLo15 CO2 Focusing Lens

Low Absorption Coatings < 0.15% (typical)

Benefits of VeLo15 (Patent pending)

Longer Lifetime

Reduced Thermal Lensing Effect

Enhance Cutting Performance

Transmit Red (650-670nm) laser line for easy alignment

For High-Power CO2 Lasers above 2.5 KW

Specifications

Lens Material Type: ZnSe

Total absorption: < 0.15% (typical)

Surface Quality: 40 / 20 both sides

Anti-reflection coating R < 0.25% @ 10.6µm per surface

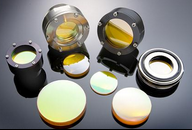

UV OPTICS

UV Excimer Laser Optics

Optics for 193nm, 248nm, 308nm applications

When working at such short wavelengths, great care must be taken to prevent the occurrence of small defects in the optical components or their coatings. Also, coating layers are very thin requiring a high degree of precision and control in their

deposition. Many common optical glasses cease to transmit at these wavelengths so it is essential to use material such as UV grade Fused Silica, Calcium Fluoride or Magnesium Fluoride as component materials for transmissive optics. The fluoride materials are soft and hygroscopic which necessitates special handling and knowledge of the material shaping and polishing characteristics.

Cavity Optics: Rear mirrors & Output Couplers

Focusing lenses (spherical & cylindrical): FL specifically designed @ 250nm

Bending mirrors (45deg) & beam delivery optics

Polarizing optics: Waveplates, Polarizing plates, Contacted polarizing cubes

Prisms for beam dispersion

Specifications

Optics with CaF2 & MgF2 material

Surface Quality: 20/10 or better

Surface Figure: lambda / 10 @ 633nm

Thin film coatings are designed for high laser damage threshold(Anti-reflection & High reflector coatings > 1.2J/cm2 @ 10ns)

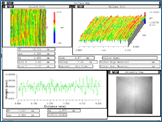

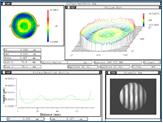

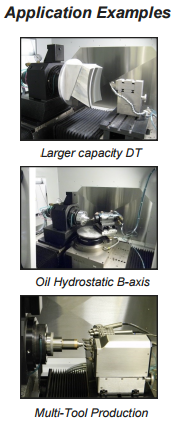

DIAMOND TURNING

We Are Turning FLIR Optics To The Next Level

We are excited to introduce our new fabrication capability line of diamond turning for IR lenses (Ge, Si, CaF2, ZnSe, Cleartran, Al, Cu) for FLIR imaging applications ranging from 2-16um used in a wide variety of markets such as electro-optics, aerospace, defense, and commercial industries. With the latest generation of Nanotech’s 450UPLv2 (3 axis), Lambda is able to support all your IR needs as a complete package including High Efficiency FLIR coatings from 2 to 16um. This system offers a 400mm diameter swing capacity great for large size diamond-turned optics from 1mm to 400mm, Irregularity (1/2 Fringe for Ø 150mm) <1/2 Fringe up to Ø 150mm, and Surface Roughness to 30 Å RMS.

We also offer the following HEAR FLIR COATINGS on DIAMOND-TURNED OPTICS as a turnkey for UV to FAR IR IMAGING applications.

* High Efficiency AR coating 3-5um (T avg. >98.5%)

* High Efficiency AR coating 8-12um (T avg. >98.5%)

* High Efficiency AR coating 7-14um (T avg. >97.0%)

* High Efficiency AR coating 2-13um (T avg. >92.0%)

Diamond Turning Capabilities

| Substrates | Ge, Si, CaF2, Cleartran, CaF2, ZnSe Al, Cu |

| Diameter (max) | 400mm |

| Irregularity ( λ@0.633µm P-V) | <1/2 Fringe for Ø 150mm |

| Radius of Curvature Tolerance | ± 0.05% |

| Roughness | 30 Å RMS |

相关资料下载链接:

![]() (NEW) F-theta Scanning lenses for CO2 lasers

(NEW) F-theta Scanning lenses for CO2 lasers

Brochures (.pdf format)

![]() Optics for Defense & Security Industries

Optics for Defense & Security Industries

![]() LaseRemap Brochure – Diffractive Beam Shaping Module

LaseRemap Brochure – Diffractive Beam Shaping Module